[youtube]http://www.youtube.com/watch?v=BjglCqFLS0g[/youtube]

ABRN and Butler Community College partnered together to provide this ABRN HOW2 training video. In this video we are going to demonstrate how to perform dent repair by useing the new Magna-Spot stud welder gun made by Motor Guard. The new gun is used with the same technique; however, it has a few new features that we will demonstrate.

Where Can I Purchase One Online?

There are several place to purchase the new Magna-Spot JO-1050 Stud Welder Gun online:

- Amazon – Amazon has these at the lowest cost I have found. You can also check with your local Motor Guard Distributor.

7 Steps To Perform Dent Repair Using A Stud Welder Gun

1. Remove coating (grinder or dual action sander) sanding takes longer, but it much safer with today’s thin metals.

2. Using stud welder gun weld several pins on the damaged area. (remember first in last out)

3. As you start pulling your indirect damage first, use a body hammer to tap down on the highs. (this also helps relax your metal)

4. Pull direct damage last.

5. Remove pins and grind any of the remaining stud welded to the panel. (do not over heat metal)

6. Grind or sand 4″ past damage area to provide a area to apply filler without overlapping paint with filler.

7. Blow repair area off with compressed area.

Now you are ready to apply your body filler, block, prime, block, and get ready for paint.

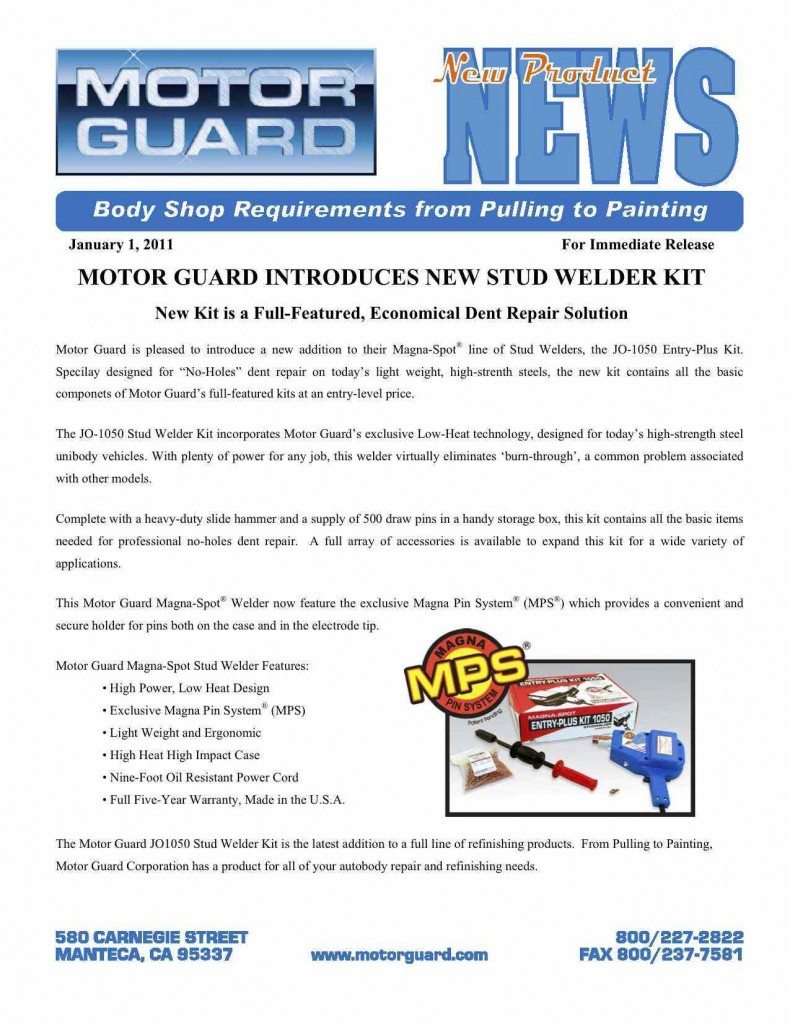

Additional Information About The New Magna-Spot JO-1050 Stud Welder Gun

Visit MotorGuard.com

LEARN HOW TO AVOID COMMON MISTAKES WHEN APPLYING AND SANDING BODY FILLER. Visit Our Auto Body Filler Training Page.