More care must be taken with thin metal used on car body panels not to over grind and thin the metal. In the past, I have ground auto parts with 24 grit, later started using 36 grit, then to 50, but grinding is still too aggressive for many of the thin metals used on today’s parts. Especially some of the aftermarket body parts.

Of course, if you are using a stud welder gun, you may have to lightly grind the stud head off, or you may have to grind a welded area. However, this should be kept to a minimal to prevent over grinding the metal making it weaker and thinner than it should be.

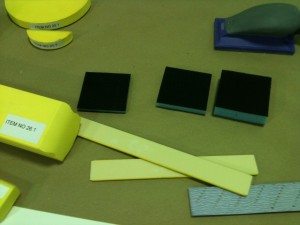

Another problem that can consume a lot of time when working with body filler is getting it out of the areas you didn’t intend for the body filler to be. You know, around edges, cracks, etc. around the repair area.

This video is going to address both of these problems and provide more tips when working with metal and body filler.

For The Complete Video Series Of This Project CLICK HERE

SCROLL TO BOTTOM FOR VIDEOS, THE STEP-BY-STEP PROCEDURE AND ADDITIONAL RESOURCES. HOOK US UP BY SHARING THIS WITH YOUR FRIENDS. CLICK THE FACEBOOK BUTTON TO THE RIGHT.

SCROLL TO BOTTOM FOR VIDEOS, THE STEP-BY-STEP PROCEDURE AND ADDITIONAL RESOURCES. HOOK US UP BY SHARING THIS WITH YOUR FRIENDS. CLICK THE FACEBOOK BUTTON TO THE RIGHT.