Dent Repair – Spray Guns – Matte Black – Estimating – Smoke Taillights – AirBrush

Auto Repair Estimate Training

Part 1 – What Is An Estimate

Auto Repair Estimates are called different things including, damage report, damage estimate, auto estimate or several other names, but they are all the basically the same thing. However, a damage estimate is more than just a sheet of paper listing the total cost of repair on it. An estimate is a contract or an agreement between two people. Just like with real estate, the owner and buyer must agree on a price and sign a contract of their agreement. A damage estimate is the same way in many ways, as there should be an agreement between the shop and customer and the customer should sign the agreement to authorize the shop to repair the vehicle. One thing that you need to explain to the customer, which is misunderstood many times, is that the total amount is just an estimate. Auto repair estimates do not guarantee the exact amount of the final invoice. There may be hidden damage or many other factors that may change before the car is completed. As an estimator, it’s your job to have excellent communications with the customer. You need to let them know that an estimate is subject to hidden damage. You must also understand that the estimate or signed agreement is only good for items that are written on the estimate. If any additional work is needed, you will need to contact the customer and agree on the new amount. This is called a supplement, which may include additional parts or labor as needed.

Methods Used To Write Estimates

We used to write all auto repair estimates by hand using Mitchell Estimate Guides. This involved writing all of the damage on an estimate and looking in the estimating guide to get all of the parts prices, and labor needed to estimate the job. Computer generated estimates have simplified and taken over the hand written estimates, but when learning how to estimate, I believe it to be crucial to learn all of the basics first, which requires estimating guides, a blank estimate and a pen. Learning to hand write estimates in the foundation of becoming an effective estimator. Just like every house or building must have a strong foundation, an estimator must master the basics first.

The Sequence of an Estimate

Most estimating guides and computer systems are set up with the same sequence. Starting with the front bumper cover and ending with the back bumper. This is important to know as you want to write the estimate in the same order to write a clean sheet. For example, if you are writing an estimate on a car that has damage in the front end, start with the front bumper and move towards the back of the car one part at a time. Bumper cover, front grill, right front fender, etc. Now when you use the guide it will be easy to follow along adding the prices and labor times.

Who Needs Estimators?

Every shop will need someone to write estimates for the customers. Some shops may have more than one estimator. Insurance companies needs the assistance of estimators as well. When you work for an insurance company writing auto repair estimates your title may be auto estimator or auto appraiser.

Part 2 – Adding Non-Included Operations

The EstimatingGuide

Once we have all of the information needed from the vehicle we can take the estimate into theestimating office or area where we can complete and total the auto estimate. The estimating guide will provide a list of the parts with diagrams, the price of the parts, the flat rate labor to replace the parts (judgment time is not-included in the estimating guides, we’ll discuss judgment time later) and the refinish flat rate to paint the parts if needed.

Parts and Abbreviations

It is very important to know the nomenclature of the parts and the abbreviations of the parts. You must also realize that parts may be called different things. A door outer repair panel may be how the guide describes what we know in body shop jargon, door skin. However, it is going to make it difficult to find the right parts if you do not have a clue what they are called. A couple of abbreviations that I am going to mention are R&I,which stands for remove and install. This is when you remove a part and put the same part back on. For example, there may not be any damage to a door, but it may have to be removed to gain access to the damaged area. Therefore, you will not have to remove the trim panel, glass, door handle, etc. This will be less flat rate than to replace the door.. If you replace the door that is called R&R, which stands for remove and replace. Now you will have to transfer all of the hardware from the old door to the new door, which is going to take more time. Many times on front bumper covers and other assemblies they have an O/H, which stands for overhaul. This basically gives you time to take the assembly completely apart and to put it back together.

P-Pages

Look at your P-Pages and to learn all of the abbreviations. This is something that will help you. You don’t just want you to memorize what they stand for, but you want to understand what does each abbreviation includes or does not include in the tasks.

Think About Walmart When Writing Estimates

What is included and what is not included in each operation? This is something that you need to ask yourself every time you add a line to your estimate. This is where most mistakes are made when writing an estimate, which results in dollars lost for the shop. There are tons of non-included operations that go unclaimed on most estimates. Many times the estimator claims they do not put it on the estimate because the insurance company will not pay for it. There is some truth behind this story, but it is usually because they did not write it on the estimate correctly. You must itemize each procedure if you plan to get paid for it. It is like going to Walmart. Have you ever went to Walmart and gathered a bunch of items in your cart, then went to check out; then they give you the amount, which almost gives you a heart attack? Well, lets take this one step further, what if they gave you receipt with just the total amount on it? You would probably claim that they made a mistake. However, when you get the itemized receipt, you look it over and realize all of the prices are correct. It just added up to more than you thought it would. I don’t know if this has ever happened to you, but it happens to me all of the time. Insurance adjusters are the same way. If it is not crystal clear what you are charging for, they want to claim that it is not right and they do not want to pay that amount…I sure wish I could do that at the store! However, if you have every item listed separate and not bulged together, they can see that your charges are legitimate. So to determine what non included operations you can add to your estimate look in your p-pages. This will list everything that is included and everything that is not included. I recommend that you take some time and study the p-pages and know them by heart.

Part 3 – Getting Paid For The Non Included Item – Get Paid For What You Do

If you write auto repair estimates for a body shop and you’re not looking though all of your not included items in your p-pages, you are leaving a lot of money unclaimed. These are operations that must be performed to complete the job. Therefore, the shop and the technician should get paid for it.

What Do Insurance Companies and the IRS Have In Common?

Insurance companies are a lot like the IRS. There are many things that the insurance companies are willing to pay for just like the IRS has many tax saving benefits for businesses. However, if don’t ask for it, neither one of them will offer to give it to you. I am not saying that the insurance companies will pay you for everything you ask for, but it is certain you will not get paid for the operation if you don’t ask for it. There may be as much not included time on a part as the time given to R&R it. Let’s take a look at an example.

The P-Pages

The P-Pages or procedure pages have a lot of useful information you need to learn. I recommend to study the p-page and learn them well. You can access the a copy of the p-pages atwww.CollisionBlast.com/pPages We are going to use one of the examples you will find in the p-pages to discuss.

Fender:

Included Operations Include

•Align to vehicle

•Fillers (if mounted to fender)

•Cornering lamps (if mounted to fender)

•Fender liner

•Scoop

•Side marker

•Side repeater lamp

Non-Included Operations Include

•Antenna

•Bumper R&I

•Battery

Emblems & nameplates

•Grille

•Header panel

•Hood Inner panels

•Lamp aiming

•Mirror

•Moldings

•Mud guard

•Road wheel

•Spoilers & flares

•Stripe tape, decals or overlays

Ask Yourself

If you are a new estimator, you need to get this list out and go over it for every part that you are replace. Ask yourself if any of the not included item are required to perform in the specific job that you are estimating. For instance, on the fender above ask: Will I have to R&I an antenna? If the fender has an antenna add time for it on the estimate. If not, don’t add it. Next, ask yourself if you will need to R&I bumper to replace the fender. If you will, add the time. If not, don’t add any time for it. Go through each item on the non-included list and ask if this task will be required.

Increase Shop Profits

Now you can see the amount of money that you may leave unclaimed on each panel. Many of the non-included items will need to be performed on each fender you replace. Of course, you would only add what applies. You would not want to add time to R&I hood, if you do not need to remove the hood to R&R the fender. Look over the list on each panel that you estimate and add what applies to the estimate. If a fender pays 3.0 hours, you may be able to add an extra .5 to 1.5 or more hours of non-included operations. This will lead to major profit for the company and technician at the end of a day. Who know how much .2 or .3 for every emblem you replace may add up to at the end of one year.

Tell A Story

The key is to list each item separately. You need to tell a story with your estimate and it needs to be easy to understand. If you try to bulk or clump items together, chances are the insurance adjuster may refuse to pay. The estimate need to show the big picture crystal clear for everyone.

Part 4 – The Labor Time Are Not Concrete – What Is Included In The Estimated Time

First of all, we call the estimating guide, a guide, for a reason. The labor times are not necessarily set in stone. If you feel the labor time or other issue is not fair you can challenge the task. There is a website for submitting your inquirers at www.CollisionBlast.com/DEG. Many times technicians and/or estimators do not feel like the estimating guide or computerized system gives enough time to perform the operation, but they just take it as the gospel as they do not know how to challenge the concern.

The Problem Will Only Be Corrected If They Know About It

If you truly feel that the guide is not giving you enough labor time, go to the above website and submit your concern, as there have been a lot of changes made to the different estimating guides due to this. The estimating software companies will never know that there is a problem with their database if we do not let them know.

Back To The Basics

We don’t need to worry if the estimating system is correct or not at this time, as we’re just getting started. I just wanted to give you an idea of how it works and that the times in the guides are not set in stone.

How Are The Times Determined?

Lets discuss how the times are determined. The time is supposed to be the time it takes a skilled technician to perform the task. However, this is for new undamaged parts. This does not include pulling damage to gained access to bolts, rusted or corroded bolts that may be harder to remove than new ones would. If this is necessary, you need to add the additional access time to the estimate.

Labor Rate

The shop labor rate is what the shop charges per hour. This varies depending on the shop as each shop is responsible for setting their own rate. In fact, it is against the law for shops to get together and discuss labor rates. That would be called price fixing. For this example, if the shop labor rate is $45, the shop would charge $135 to replace the fender. We will talk about paint and material charges later.

Estimating Times

All estimating guides use tenths. You may see 2.3, which is 2 hours and 18 minutes. There are 6 tenths in an hour so multiply each tenth by 6 to determine the time in minutes. .5 equals 30 minutes and 1.5 equals 1 hour and 30 minutes. This gives us an idea of how the the labor times are determined.

Part 5 – The Necessary Information – What Needs To Be On An Auto Estimate?

There are many different styles of estimate forms, but they all help you record the necessary information. All auto repair estimates will need to have your company information on it. It should also specify who the auto body estimator is and the estimators contact information. It will need all of the customers information: including their name, address, phone numbers, or any other contact information. I even like to get their e-mail address. The more contact information that you receive from the customer up front, the easier it will be to follow up or update the customer at a later time.

One Thing To Avoid

The last thing you want is to be hung-up needing to speak to the owner before you can continue the repairs; only to discover that you can not get in touch with them. Perhaps they go on vacation and the only contact information that estimator recorded was their home phone number. You will not have a happy customer when they return expecting their vehicles to be ready.

Vehicle Information

You will also need the vehicle information. The make, model, and style. Be certain to record the VIN(vehicle identification umber) number. This may be used to determine the correct parts to order and many other uses. The VIN can actually tell you quite a lot about the vehicle. Record the mileage, license plate number and the date. This is all important information to have for future purposes.

Insurance Information

Most accidents are going to be a insurance claim so be sure to get all of the insurance information. Insurance name, contact information, loss date and type of loss.

Get Information About The Accident

Before you start writing the damage find out as much information as you can about the accident from the customer. The customer or whoever was in the accident is the best resource to get the information that you need to write a good estimate. A few of the questions that you may ask include are: how many passengers were in the vehicle? You may need to examine the seat belt where a passenger was sitting. How fast were you traveling? Or, was the vehicle parked? What direction was each vehicle traveling upon impact? All of this information will help you have a better understanding of the accident and will help you write a better estimate.

A Communication Tool

Think of the estimate as a communication tool that will show the big picture. The more information you have on it the clearer the big picture will look. The more customer information, vehicle information, insurance and facts about the accident you collect, the better communications you will have throughout the entire process. A little extra work on the front side will save you a lot of time and headaches.

Part 6 – The Significance of Doing Your Best To Generate Auto Estimates

Once you have all of the information you need about the accident you may choose to assist the customer and help them with a rental car or offer to give them a ride back to work or to their home. It may not be necessary for the customer to be there while you write the estimate. This is where many shops are rethinking the way they write estimates. Rather than have the customer waiting and the estimator rushing through the estimating process so the customer does not have to wait long. Now many shops are assisting the customer with a rental car or a ride. This allows the estimator to write a thorough estimate, which may require disassemble of parts and/or raising the car off the ground to determine extent of damage. For example, the estimator or a technician may need to remove the front bumper to determine what parts are damaged behind the bumper cover. By inspecting the damage this way, you should have a very thorough estimate when completed. Before putting the car back together you may want to contact the customer (if you did not already have the customer authorize repairs) and discuss the repairs needed with them and and the steps necessary to have the car repaired. If an insurance company is involved, you will also want to discuss repairs with them as well. This will let the insurance know that the customer has already authorized your shop to perform the repairs. If the insurance company demand that the car be taken to another shop, simply ask for the time spent tearing the car down and putting it back together. Chances are they will leave the car at your shop.

This is getting a little technical for now, but just wanted to give you an idea of how it may work in the industry. There is currently a fight going on with the shops, as some insurance companies are trying to determine where the car will be repaired. However, that is called steering and it is illegal. But that does not seam to stop the insurance companies for doing it. This is definitely for another discussion or lesson.

The main point of this lesson is to write a thorough estimate as it serves many purposes. With today’s complex cars, the days of writing a visual estimate without tear down are gone. Cycle times and the lean process are moving away from unnecessary work, which includes writing supplements on every vehicle that you work on. A well written estimate will also give your technicians a better idea of what all they need to do to the vehicle. The estimate serves many purposes, but a communication tool should be a vital purpose. A communication tool between the shop, customer, insurance company, and the technician. Now that you see how importance of the estimate. Therefore, you should try your absolute best on every single estimate that you generate.

Part 7 – Computerized Auto Estimates

Do you remember when businesses started implementing more computers? I kept hearing of how much paperwork this was going to save and how much easier the computers will make our work. Well, years later I’m still not fully convinced of that theory. It seems like we have more forms, files, and paperwork than we ever had before. I keep hearing paperless, but I am not seeing it. I think perhaps every item that goes paperless, there are two or three additional things come up that we must manage. However, I do like the ways computers work and believe that we keep better records of everything. I think that we did not have a lot of the work because we were just not doing it. We really have all of our records at our fingertips even though it seems like a lot of work to manage. It was painful getting to this point as an estimator. I remember the first computerized estimating system that Mitchell came out with. We had twice the amount of estimating guides to pack around and we still have to flip through the pages to swipe the bar codes. I did not like that system, but the systems that they have today make it much easier to write auto repair estimates. I mean, who can’t point and click?

One of the advantages of computerized auto repair estimates is that there are no errors. Well, an auto estimator can still leave a lot of money on the table by not adding non- included operations, but computers have eliminated all of the calculation errors. It is pretty hard to misplace an estimate when it is stored in your computer as well. Therefore, computers are more accurate and remove much of the human error out of the equation.

Most computer estimating systems update their information on a monthly basis. As fast as the parts prices can change this is a big benefit as well. When we used the estimating guides, they were sent out every three months, which would be outdated before you received your new copy. The computer also eliminates a lot of writing. Remember I said to list each item separately in an earlier post? Now you may only have to type a few of the operations that are not in the system. However, you can point and click most of your estimate with ease.

The internet also made it possible to work directly with insurance companies. Both the shop and the insurance can look at the same estimate online. They can also view digital photos. This was the birth of Direct Repair Program (DRP). This started out as a good thing, which allowed shops to partner with insurance claims handling process, but the program took a different direction in my opinion. Insurance companies started demanding discounts and requiring the customers to use the shops that they had relationships with. Again, that is another subject that we may discuss at a later time. The internet and computers along with digital cameras have simplified the claims process.

Part 8 – What About Time Not In The Estimating Guide?

What about labor time not in the estimating guide or estimating system?

Not every operation is going to be included in the estimating guide. For instance, the labor time for all of the dent repair, plastic repair, frame repair, and many of the non-included operations in the p-pages are not in the guide. This is where experience steps in. When you have to determine the time it should take to repair a dent on a right front fender is called judgment times. Because you are the judge and make the call. Therefore, judgment times can vary greatly from shop to shop or estimator to estimator.

Different Labor Rates

We already discussed that shops are responsible to set their own labor rates in an earlier post. Although, most shop charge different rates for the different types of operations they perform. For example, a shop may charge $45 for body labor, $45 for paint labor, $65 for frame and structural repair labor and $75 for mechanical labor. As an estimator it is important to determine what each operation is to assure that it is labeled correctly. Many estimating guides have a “m” for mechanical operations and a “s” for structural operations. However, you must make sure that it is added into the correct category or you may not charge the different amounts. Therefore, if you are charging $45 for every operation, you’re shop and technicians are not making as much money as they should be making. Small details like this can add you to a lot of additional income over a week or month time period.

Part 9 – Vehicle Information

Make and Model

Record the make and model of the vehicle. Is it a coupe, sedan, etc.? You will also want to record any packages that the vehicle is equipped with.

Decoding the VIN

The VIN stands for the Vehicle Identification Number. This number tells a lot about the vehicle. There are 17 characters in a VIN and each charter tells something about the vehicle. This will vary depending on the manufacture, but the first digit will let us know what country the vehicles was made in. The 10th digit will always let us know the year model. To determine what all of the charters stand for you can look in the p-pages. This will help us decode the vehicle. If you’re using a computer system, it will probably decode the VIN for us. In CCC Pathways you must put the VIN to complete the estimate. Once the VIN is put into the computer correctly, CCC will decode the VIN for us. If you recorded the VIN wrong, you will not be able to proceed. So it is important to record it correctly. Writing it down correctly will also save you another trip to the car. Visit your p-pages to help you de-vin the VIN. A correct VIN will also help you when ordering parts to assure you are ordering the correct parts. Mis-odered parts is an ongoing issue, which delay repairs, increase recycle times, and may break a promise date of completion to the customer.

Why Record Mileage?

Recording the mileage is easy to overlook when writing an estimate. However, it is important to get the mileage for several different reasons. The reason that I always like to record the mileage is for documentation. I have heard of customers claiming that their vehicle was drove around town using all of their gas. It may be necessary to test drive a vehicle before returning it to the customer, but with the mileage recorded before repairs were made will give you documentation of actual miles the car was drove while in the shop for repairs. Always document everything, as it may cover your tail at a later time.

Date of Estimate

You will also need to record the date the vehicle was estimated. Normally an estimate is only good for one month. With price changes, the estimate may become invalid with incorrect prices, which will need to be adjusted. Another reason it is important to recorded the date the estimate was written is because the condition of the vehicle can change. For example, when you wrote the estimate, the vehicle may have had surface rust. Several months later the rust may turn into a panel that needs to be replaced or additional labor to repair the damage.

Prior Damage

Prior damage is damage that was present before the accident occurred. This is important to discover as insurance will not pay for prior damage. Prior damage may be on adjacent panels or it may be on the damaged panel that you are estimating. For example, if a vehicle has a small dent on the front of the right front fender with prior damage on the back of the right front fender, the insurance will not pay for the repair time for the damage to the rear of the fender. The damage will probably need to be repaired, but it will be at the cost of the customer, not the insurance companies.

Finding The Paint Code

Paint codes can be in various locations depending on make and model. The p-pages or your estimating system will usually give you the location of the paint code. You will need to know if the car has clear coat, tri-coats or quad coats. This will all change the cost of paint labor and paint material costs, which we will talk about later.

Part 10 – The Different Types of Damage

I have briefly mentioned the different types of damage in previous blog posts. However, I would like to take some time to thoroughly discuss the different types of damage to look for when writing an auto repair estimate.

The most obvious damage is going to be direct damage. This is the point of impact, which is very easy to identify. When repairing a vehicle, we have the first in last out rule. The point of impact would be the “first in” location of the damage. Therefore, this should be the last area to be repaired. The reason you need to know this as an estimator, is because if there is direct damage, there may also be indirect damage. This is the secondary damage, which is harder to identify. This is the damages that is caused by energy transfer during the collision. This may include buckles, popped spot welds, cracked seam sealer, and misaligned panel gaps. On unibody vehicles, secondary damage can occur throughout the entire vehicle, which will require a thorough inspection. There are actually five different damage zones during an accident.

•Zone 1 is the direct damage as mentioned above, the point of impact.

•Zone 2 is the indirect or secondary damage, which is cause from the force and direct damage.

•Zone 3 is the mechanical component damage. I am sure that you’ve heard the law “an object in motion tends to stay on motion”, well your mechanical components like your engine, transmission, drive train, can cause damage when in an accident. If the engine is traveling at 5o mph and the vehicle comes to a sudden stop, the weight of the engine is still wanting to travel at 50 mph. This can cause damage to motor mounts and other attachment points.

•Zone 4 is the passenger compartment. The same Newton law applies to people in the vehicle too. Passenger can cause damage to seat belts, knee bolster panels and other interior parts. This may also result in airbag deployment, which requires additional operations to repair the vehicle.

• Zone 5 included exterior components and trim. This is items that are attached to the vehicle. This is additional items that can be damaged or create damage during an accident. Another thing you may consider when inspecting the vehicle for damage are items in the vehicle. Were there heavy items in the trunk space or in the passenger comportment? A flying tool box can create damage to the vehicle. These are some things to keep in mind when writing auto repair estimates. Go through each zone in your head looking for damage to the vehicle.

Next we’ll discuss the predictable reaction a driver.

Part 11 – Accident Sequence

There are no absolutes when it comes to auto accidents. Although there are some predicted actions that a driver usually makes during an accident. If you are traveling down the road and you see a car coming towards you, what are you going to do? Chances are that you will hit your brakes and/or turn away from the oncoming car or object. That is what most peoples natural response is without thinking about it. If we consider that first action is hitting the brakes, it can help us determine what damage may be present. As you slam on the brakes you transfer the momentum of your car to the front as it goes down. While the front goes down the rear raises higher. When the impact happens it is a safe to assume that the damage will be higher than if the brakes were not applied, which may cause more damage to transfer through the upper part of the vehicle and cause sag damage to the vehicle. However, many people have another response as well. You are normally going to turn your wheel away from the oncoming vehicle. As you do that, your car is now at an angle with the front end down and the rear high when the impact occurs. Now it is safe to assume that the vehicle may have side sway damage as well. If you keep this sequence of reactions in mind as you begin inspecting the vehicle with the 5 zones as mentioned in the previous blog, you will begin to have even a clear idea of what damage may be present and what to look for. This will help you generate a more thorough auto repair estimate.

Part 12 – Generating The Estimate

Begin the inspection

Now you know what types of damage there may be and the sequence of predicted damage that may be present, we can begin to write the auto repair estimate. We have all of the customer information, vehicle information, and insurance information recorded on the estimate form. We have asked the driver of the vehicle all of the questions to determine what happened during the accident and any additional information that you may need. Now it is time to start writing the auto repair estimate. First you want to inspect the vehicle looking for all direct and secondary damage.

This may include:

- Raising the vehicle up to look underneath the vehicle

- Looking inside the passenger compartment, measuring to determine if any frame or unibody damage is present, determine the severity of the damage.

- Visual inspect all body gaps for misalignment’s, popped loose spot welds, cracked seam sealer, etc.

Once you have the big picture you can start writing the damage estimate report. Start with the the damage that is near the front of the vehicle first and move backwards. For example, if the door, rocker panel and rear quarter panel are damages, write in that sequence. Most estimating guides and computer estimating systems follow the same sequence, front to back. Record everything that needs repaired or replaced on the estimate. This may require removing parts to determine if there is damage to the parts that we can not see. Open all doors, hoods, and the deck lid. However, if the customer is going to be driving the vehicle after your inspection, you may not want to pry or wedge any parts open to gain access. This may lead to a panel that will not shut properly, which may be a safety hazard. Be sure to explain to the customer your concerns and let them know there will probably be hidden damage upon tear down, which will require a supplement estimate to be generated. As we mentioned in an earlier post, you may consider helping arrange rental or providing a ride for the customer once you have all of the necessary information from them. If you get the customer to go ahead and sign authorization for repairs, you can take your time and thoroughly write a clean estimate, which may require partial tear down. Once you have an auto damage estimate generated, you can consult with the customer and insurance adjuster to determine the next step of action to take.

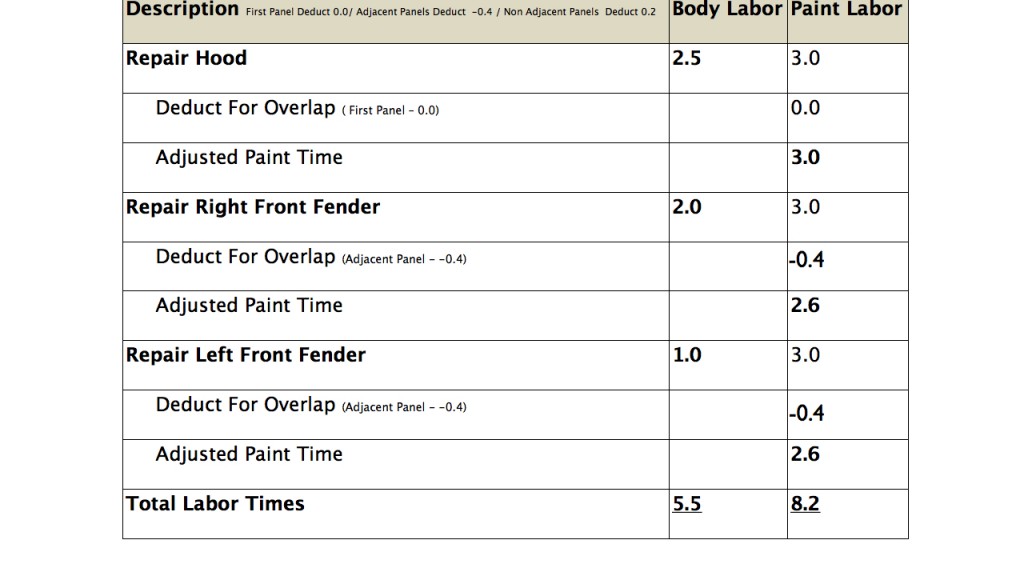

Part 13 – Deducting For Overlap

Paint times are given in the estimating guides as well. In the Mitchell estimating guides, the refinish labor time, R&I time, O/H time are usually right under the title of each part. The R&R time is usually listed with the part. All paint times are determined for painting one panel at a time. However, many times we paint more than one part at a time. For example, if a car was hit in the front it may damage the hood and both front fenders. Therefore, three parts would be painted at the same time. Would it take the same amount of time to do all three panels at the same time as apposed to pulling the car in and out of the booth three separate times? Of course it would save time. You would only mask once, mix paint once, spary the paint once, and clean your spray gun once. Therefore, we should deduct part of the time for each additional panel that we paint. The first major panel will not have any deduction for overlap. However, each additional adjacent panel, the estimator needs to deduct .4. If it is not an adjacent panel, the estimator will need to deduct .2. In the example above we have a hood and two fenders. Let’s say the guide gives 3.0 for each panel. With no deductions you would total 9.0 refinish hours. That would not be correct and adjustment would need to be made. Let’s figure this deducting refinish labor correctly. The first major panel is the hood, which give us 3.0 hours. The next adjacent panel is the fender, which gives us 3.0. Since this is an adjacent panel, we will deduct .4 giving us 2.6. The next adjacent panel is the other fender, which gives us 3.0. We will deduct .4 from that time as well giving us 2.6. Now your total paint time will be 3.0+2.6+2.6= 8.2. This is .8 less time that we will charge after deducting overlap. Remember that panels that are not adjacent to the panel your painting will only have .2 deducted per panel.

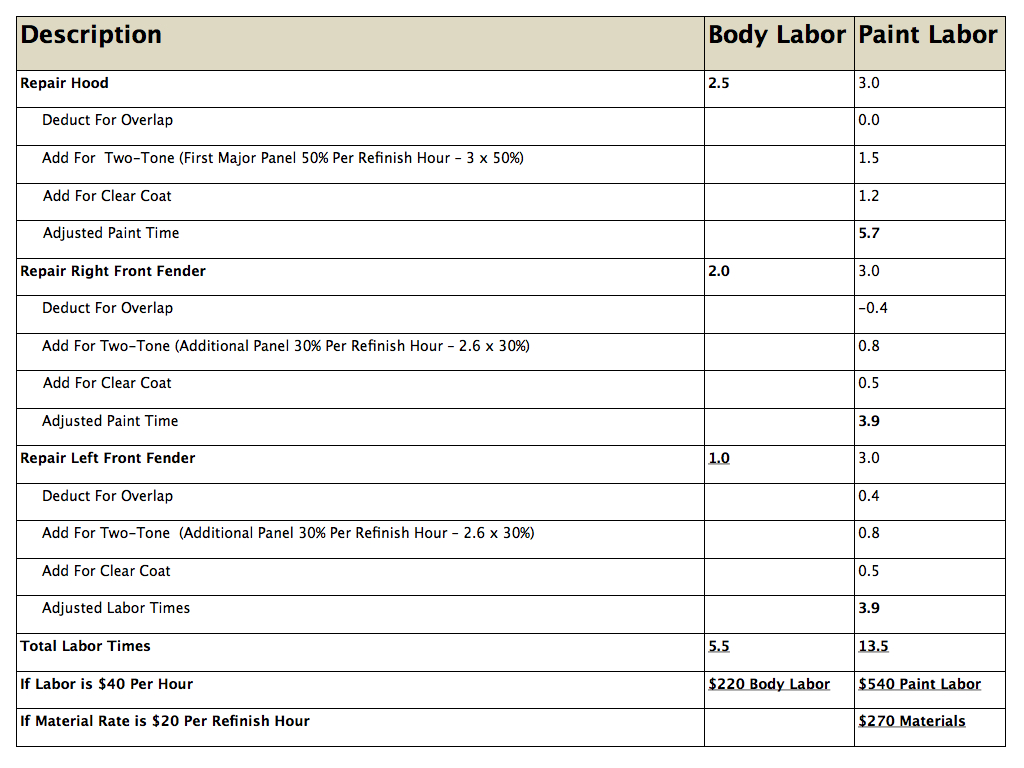

Here is an example of how this works on an estimate.

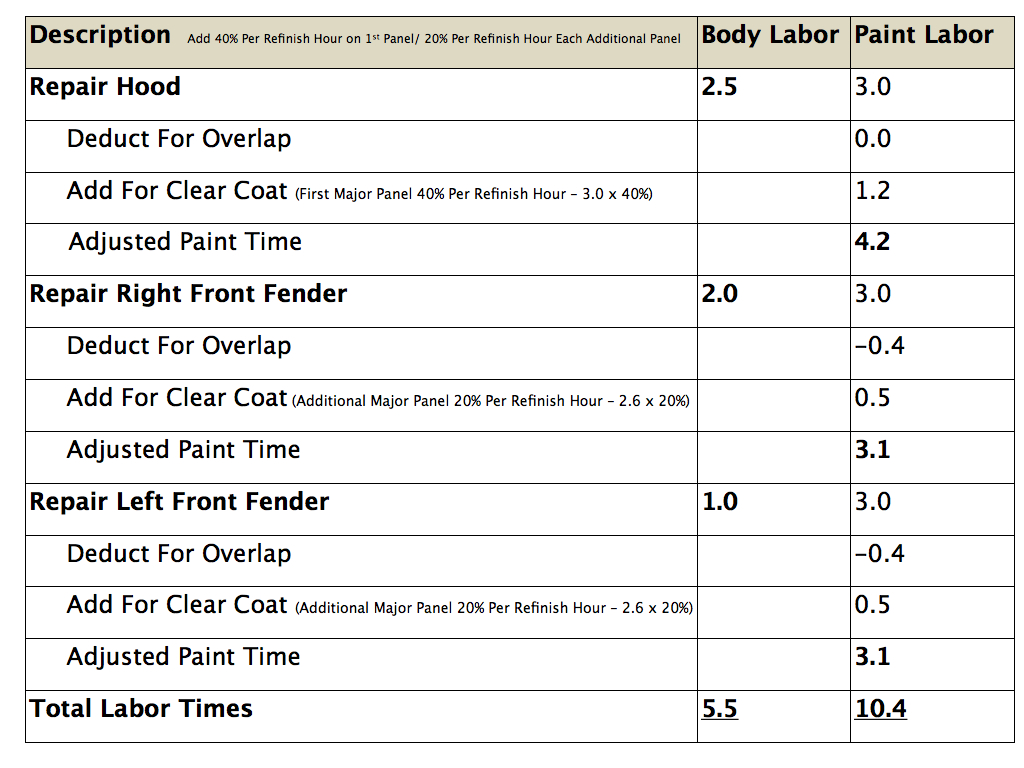

Part 14 – Adding For Clear Coat

When writing auto repair estimates the auto estimator must add for clear coat. The clear coat takes time to spray onto the vehicle and it is expensive. Therefore, there should be a charge for the time that it takes to mix and apply it and a charge for a cost of the material. The time should be added to refinish labor to accomplish both labor time and material charge. We will discuss how to determine the material charge later in another blog.

Today we are going to explain why you must add for clear coat and how to determine how must time to add. You may be thinking that most vehicles have clear coat; why don’t the guide include the time it takes to clear? This is because not all cars have clear coat, and you should not get paid for an operation that you did not perform. I think it is fair for technicians to get paid for everything that they do, but if we start charging for things that we don’t do is fraud and can lead to a lot of trouble. So if you’re going to add for clear or any other not included operations, make sure it needs it.

If you clear one panel, you will need to mix your clear, tack the surface that your spraying spray the clear on the panel and clean your spray gun. To add for clear coat you add 40% of the time given to paint the panel. If you spraying a panel with 3.0 hours, you would multiply 3.0 x 40% = 1.2. So to paint and clear this panel you have 3.0+1.2 = 4.2 Total Paint Time.

For each additional panel you will need to deduct for overlap then add 20% for clear coat. For example, if the adjacent panel gives 3.0 hours we will deduct .4 to give us 2.6. Now multiply 2.6 x 20% = .5. Add 2.6 + clear time of .5 top get a total of 3.1 paint time to paint and clear the adjacent panel. This same formula will apply to each additional panel. Deduct overlap and multiply by 20 %.

Let’s take a look of the example in the previous post.

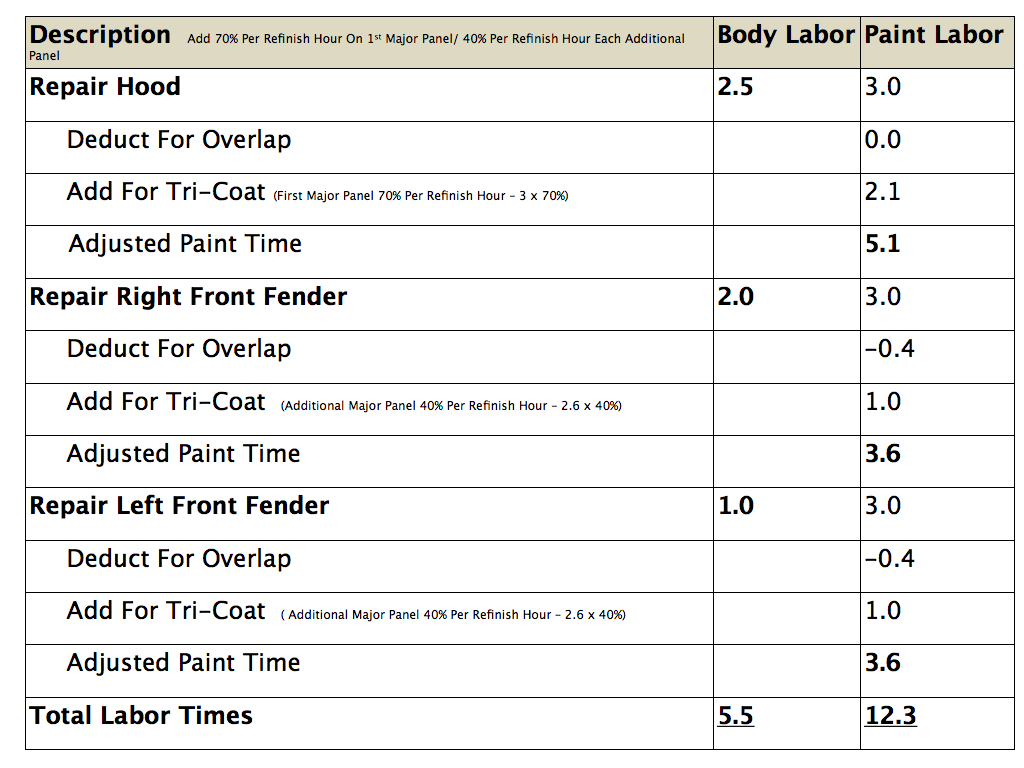

Part 15 – Add For Tri-Coat

Adding for tri-coat or three stage paint is similar to adding for clear coat. However, you will need to know when to add for clear coat and when to add for tri-coat. Tri-Coat consists of base coat, mid-coat and clear coat, which is three different operations that you must do to get the paint to match. The mid-coat may be a pearl coat or a tinted clear to create different effects, including shifting colors and adding more depth. It may be very difficult to determine by looking if it is a tri-coat or not. To be certain if you are charging for the correct operation is to locate the paint code on the vehicle and look it up. The paint code is NOT part of the VIN number. It is a code that is located in various places on a vehicle. The p-pages will give you some general ideas of where these paint code labels may be located and will help you identify tri-coat colors.

When adding for tri-coat you do not add for clear coat. The clear coat time is included in the tri-coat application. Use the same formula by deducting for overlap and for adding clear, except add 70% per refinish hour to your first panel and 40% to each additional panel.

Let’s examine the same example that we’ve been discussing with tri-coat.

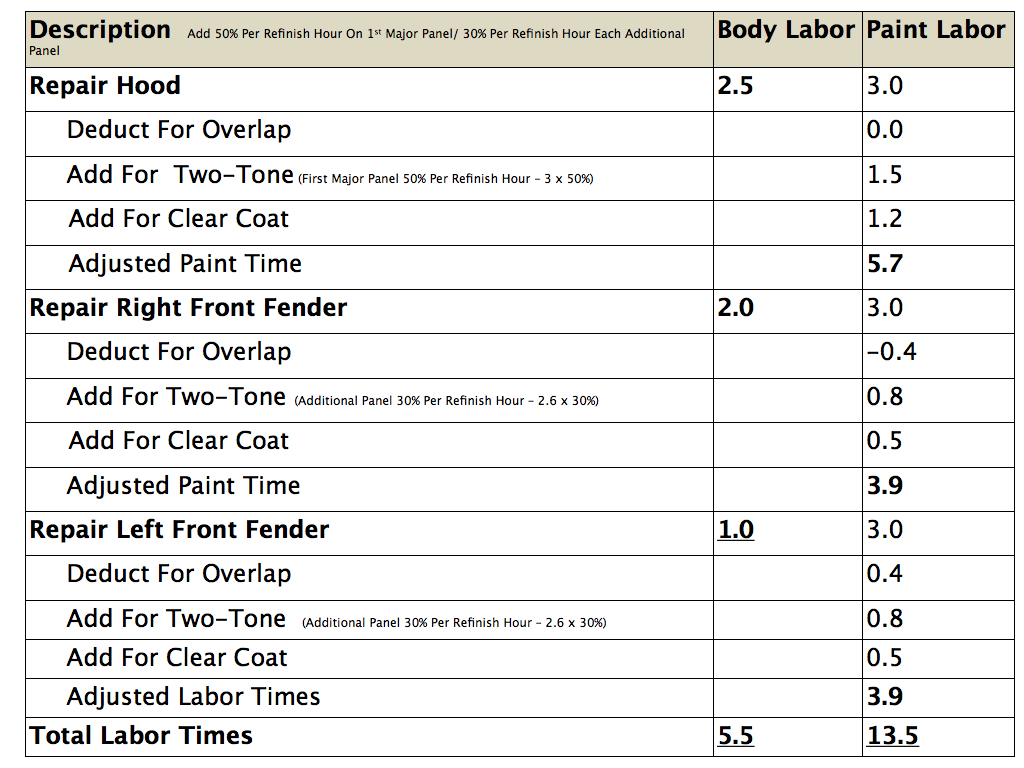

Part 16 – Adding For Two Tone

Two tones are not included in the time given to refinish a panel. Two-tone means when there are two different colors on the vehicle. Again, we use a simple formula to determine the time to estimate for this operation. Before we discuss two-tones I am going to touch on edging and painting the undersides of panels. In all of the examples that we have had, we only repaired the parts. Normally when you repair a part the jamb or inside of the panel does not need to be repainted. However, any time you replace the part it will be necessary to paint the inside. For example, if we replace a right front fender and it pays 3.0, that does not include the inside. All you need to do is look in the estimating guide and it will give you the time to for edging or to paint the inside of the panel. The right front fender may state to add .5 for edging. This would give you a total paint time of 3.5 to paint the right front fender.

Now back to two tone. The reason that I mention edging now is this. Many new cars have different color schemes for the insides of the panels. Therefore, you should be able to add for two tone. I don’t know if shops are adding two tone for this operation, but it may be something to consider. To add for two tone add 50% per refinish hour for your fist major panel and 30% for each additional panel. Basically, it is the same formula as clear coat, just different numbers to plug in. However, this does not add the clear coat as tri-coat does. It is possible to have a single stage two tone so clear is not figured into the two-tone time.

If the first panel gives 3.0 to refinish the panel, you would multiply 3.0 x 50% = 1.5. Then you would add for clear coat by multiplying 3.0 x 40% = 1.2. This would give you a total of 5.7 hours to paint, two-tone and clear coat the panel.

Let’s take a look at the same example that we’ve been working on and determine what the refinish time will be with two-tone added.

Part 17 – What To Charge For Materials

Itemizing Materials

This is an evolving process as we determine what we should charge for. There are systems available today that we did not have when I used to write estimates. Systems like PMC Logic will help you itemize the materials actually used on a repair. This makes it easy for the insurance adjuster and/or customer to see exactly what all materials were needed to repair the vehicle. However, if you do not use a system like this you must be certain to write everything that you use on the estimate. If we state exactly what we use and charge for it, chances are that insurance company will pay for it. Remember, they need to CYA too. If they can show their supervisor why they paid a certain amount for materials, this will make it easier for them as well. If fact, I have had several adjusters tell me that if the materials are itemized on the invoice, they will pay it. However, lump summing everything together in one line called materials needed, will not go far when the insurance company sees the invoice. Just like my Walmart story. To determine if you were overcharged or not, you need to see exactly what you were charged for. Once you see that everything looks right, you feel better about paying that amount. However, if Walmart gave us a receipt in one lump some, we would probably think that they were wrong.

Traditional

The way materials have traditionally been charged for is from your refinish labor. You take the total amount of refinish labor hours and multiply it by a determined number. We used to multiply it by 50% of the refinish labor, but with the increase materials costs, the number is usually higher now. For example, if the refinish labor is $40 per hour, the charge for materials will be $20 or higher for materials. So if you charged 3.0 hours to paint a fender and materials charge rate is $20.00, then the material charge will be $60 for paint materials.

What Is Not Calculated

What this method does not pay for is any adhesives, fillers, clips, etc. that you may use. With the price of these material, you can lose money if you’re not careful. Therefore, be certain to add the materials that are not included in the refinish labor time. Another thing that can cost you is not charging for all of your refinish time. For example, if no time is given to refinish a frame rail, you lose refinish time and material charges. If you overlook a half hour of labor (.5) this will cost you 20 dollars labor and 10 dollars materials for a total of 30 dollars. If you overlook something small like that 4 times a week that is $120 loss to the shop that week. If it happen more than that, then I think you can see how this could cut profits.

Charging For Materials From The Refinish Time

Let’s take a look at the same example that we’ve been working on and determine what the material charges will be. Were going to use $40 for the labor rate and $20 for the material rate.

13.5 is the refinish time

13.5 x 20 = 270 (if the material charge is 20)

So the material charge for this job would be $270.00

Part 18 – Nothing Happens Until The Sale Is Made

We have been discussing how to write an auto repair estimate. We’ve reviewed how to treat the customer. Now let’s get down to what is going to make or break you as an auto estimator.

It’s All About Sales:

Many auto estimators understand that a big part of their job is to provide stellar customer service. I don’t think there is a question about that. However, it takes more than being a nice guy. An auto estimator must wear many different hats and one of them, or perhaps the most important is to be a good salesperson. Let’s face it, “nothing happens until the sale is made.” If there are no sales, there is no business! I know estimators may not like the thought of being a salesperson, but if you want to be a top performing auto estimator and bring a lot of jobs in for the shop, sales it is.

My Shop Sales Itself:

You may have the nicest shop in your area with all of the latest and greatest equipment, a comfortable waiting room with all of the extras, properly trained technicians, and provide excellent customer service. However, this may not be what the customer considers when he or she decides where to have their vehicle repaired. Sure, I agree that these things are important and it may help influence the customer to use your auto body shop, but don’t assume the sale has been made.

How Does This Benefit The Customer:

If you think about it, a nice facility does not really benefit the customer. What if they think, this business is doing so good, they don’t really need my business! Then they decide to help out the little guy…because they feel like they are making a difference or helping someone out. So if you are the big shop, you need to let the customer know and feel their business is needed and will be appreciated. You will also need to convey how doing business with your body shop is going to benefit them. If you are a smaller shop, the same principles hold true. For example, you may have the latest frame machine and measuring system; however, the customer may not understand what the benefits of that are. They don’t really care if you spent xxx amount of dollars on this equipment. They want to know that by using this equipment, their vehicle will be repaired back to the factory specs and back to the pre-accidental condition so they do not have to worry if it will drive correctly or not after repairs. They want to know that their vehicle will react the way it should if ever involved in another accident again to keep them and their family safe. Then perhaps, understanding that you have the equipment to assure this is done properly and you have trained technicians to perform the work is a benefit. So don’t sell customers on your business without conveying how it is going to benefit them.

Don’t Assume The Customer Automatically Knows The Benefits:

As an estimator, all of the insurance jargon, accident procedures, body shop repairs, etc. is an everyday thing to you. It is easy to start thinking everyone knows the procedures and what to expect from your business. However, this may be their first accident; or their first time at your shop. They may not have a clue of what to expect from your business. For example, you’re probably going to clean the vehicle after repairs. Most shops do wash the car before returning it to the customer. Why not make that a benefit? Tell the customer that after their car has been repaired, you are going to have it washed and cleaned, which will have it looking better than it did before the accident. That is a benefit, but they will not realize it until you tell them. I’m sure that all of the shops would have cleaned the car, but they chose your shop because you are the only one that told them. I am not saying that every customer is going to choose you because you mentioned a car wash, but let them know the things that will set your body shop apart from the other shops. Don’t assume they already know these things.

What Are Your Priorities?

To make things happen in this competitive business work on you sales skills. An auto estimator has a lot of responsibility on their shoulders and are caught in the middle of everyone (customer, insurance adjuster, shop manager, technicians, etc.) and are extremely busy. But don’t put the sales skills lower on the priority list, as nothing happens until the sale is made.

PART 19 – 4 Tips To Help You Make More Sales

Tip 1: Don’t Judge Your Customers-

I think that we have all been guilty of this, but we need to work on it. For instance, we may think a customer is getting an estimate for the insurance so they can pocket the money or go to a competitor. We may take a look at the vehicle and determine they will not want to spend the money or don’t have the money to have the repairs performed. For whatever reason, estimators may jump to conclusions at times and believe that this customer is a waste of their time. Therefore, rushing the process and getting them out the door as soon as possible so they can try to make a sale with someone that is going to have repairs performed. I am not saying that every job is right for your shop. For instance, your body shop may not perform restoration. The best thing to do in a situation like this is help them find a shop that will perform the work for them.

This reminds me of a story I heard from a guy named David Dykes. One morning in 1956 a rough looking guy walked into a Cadillac dealership in Tennessee. The guy was poorly dressed in dirty overalls, muddy boots and was wearing an old hunting cap with his hair sticking out of the sides. He walked around the dealership for awhile, but no one came to help him. In the meantime, the salesmen were standing over their watching him. They were waiting for the man to leave. However, the guy continued to look at the cars, so the manager finally told the newest salesman to go ask the bum to leave. But instead, the salesman went over and asked the guy, can I help you. The guy asked a few questions about the cars and the new salesman politely answered the questions. Then the guy in the hunting cap asked, do you take cash or checks? The salesman almost laughed, but instead, the salesman politely said, we accept cash or check. The guy said fine, I will take a Cadillac in every color you have in stock. The guy in the hunting cap was Elvis Presley and the new salesman sold 6 Cadillacs that day. So the salesman’s kindness paid off. And perhaps your kindness may pay off too. You may not accidental sale a repair job to a celebrity as in this story, but you may make a sale. Perhaps the customer was planning to take the car somewhere else to have the repairs made, but with your sales ability, the customer decided to trust you and leave their car with you.

Tip 2: Don’t Assume You Know What The Customer Wants-

I have mentioned you need to sale the customer on the benefits, but don’t assume every customer will see the same things as a benefit. For example, we used the car wash. That may be the sale for one customer, but perhaps another customer already knows this service is provided at other body shops. Therefore, they don’t really see that as a benefit that sets your shop apart from the others. So how are you going to know what motivates your customer? It is simple; you ask them…or sometimes just listen. Many times the customer will want to explain their situation to you. The absolute worse thing you can do is cut them off. Sure you hear the same stories over and over, but if you will listen close, the customer may say little things, which are their hot spot. For example, the customer may express a big concern of how they are going to get to work while their vehicle is being repaired. If you have loaner cars; sale them on providing them with a car. Or how you are going to contact the insurance company and rental company for them so they will not have to worry about it. But don’t make this your one and only sales pitch for every customer. Perhaps the customer has 4 other cars to drive. In that case, a rental car is not going to be a hot spot. So work on selling the benefit to your customers, but if you find a hot spot, make that your focus.

Tip 3: Don’t Be To Helpful-

I remember one time I wanted to purchase a new computer. I had already done the research and knew exactly what I wanted. I walked into the store with every intention to buy a new Mac computer. I walked in and a salesman greeted me and asked if he could help me. I told him I was interested in a Mac computer. The guy was nice and tried to be helpful and explained how Mac’s were much more expensive than many of their other computers they had in stock. He explained everything wrong with a MAC and kept suggesting different computers. However, what he didn’t know is that I was already sold on the MovieMaker program Mac offers and that was the main reason I wanted the computer. He did not know because he did not ask. He was trying hard to make a sale, but I had to politely tell him, I was still thinking about it. I left the store a little confused…do I want a MAC or not? I thought about it for several days and decided to go ahead and purchase what I had originally intended. In fear of this salesman trying to sale me something economical, I went to another store to make the purchase. I am sure the salesman sincerely believed every customer’s biggest concern was the price. Which price is a concern of mine, but my biggest concern was something else….that only MAC offered.

Tip 4: Make The Sale Early and Often, But Know When To Stop-

We’ve already discussed a method to sale the customer. If you remember from earlier articles, you can try to make the sale before the auto estimate has ever been written. When the sale has been made….stop! Do not think you have to continue to sale every benefit your company has to offer them. They are sold and now they want service. If the customer authorizes you to do the repairs, take your salesman cap off and put your customer service cap on.

It’s Like Going To The Grocery Store – A Little Bonus!

These are a few general tips for you to consider. Every body shop business is going to have their own methods and ways of doing things. Just keep in mind, if the body shop is going to make money, sales have to be made. I once heard an analogy that I would like to pass on. Advice is like going to the grocery store. When people give you advice, including me, use what works. If it does not work for your needs or your business, don’t use it. But, ALWAYS listen to others and determine if it right for you or not. When you go to the grocery store, you certainly don’t want to put every item in your basket do you? No, you get the things you need and leave the things you don’t need on the shelves. On the flip side, you don’t want to leave the store every time with nothing in the basket either. So when someone is trying to give you advice, is your basket too full, just right or empty?

Part 20

PODCAST ESTIMATE SALES MAY NOT = PROPHET

Lesson 21

We have discussed all of the parts of the estimate, customer service, sales, and now we need to briefly discuss vehicle construction. As an estimator, it is important to know how a vehicle is designed, the different types of frames, the different metals and composites that are involved with modern day vehicles.

Crush Zones

Crush zones are built into the vehicle frames and parts to give upon impact. The crush zones crush and slow the vehicle before the sudden stop, much like an impact absorber. As an estimator, this is important to understand, as you do not want to section in a crush zone area, as this may disturb the original integrity of the vehicle. If the vehicle is involved in another accident, it should react in the same way for before.

Identifying Crush Zones

Crush zone can be a number of engineered designs. For instance, it may be a indention in the part, holes, dimples, slots, etc. However, one thing you need to be aware is some vehicles are being produced with crush zones you can not see. This is designed with (((()))) The metal is actual thinner in the crush zone areas and thicker in the areas where more strength is required. The only way to determing these toy of crush zones is to look at the repair procedures for that specific vehicle.

Sections of a Vehicle

There are three basic sections of a vehicle. The front (from the front windshield area to the front of the vehicle.) The center section also referred to the passenger compartment, (from the front windshield area to the back glass area.) The third area is the rear section, (this is from the back glass to the rear of the vehicle.) As and estimator this is important to know because the front and rear sections are designed with the crush zones. And the center section is designed to be stronger to keep the passenger safe. The front and rear sections are designed to absorb energy and the center section is designed to transfer energy. Therefore, most of the damage from an accident will be in the front and/or rear sections.

Front Section

If remember we discussed the front section takes most of the impact absorb of the impact as it is built with crush zones that will crush and twist to absorb energy while transferring energy around the stronger designed passenger compartment keeping the passenger safe inside the vehicle. So let’s take a minute to talk about the parts that consist of the front section. Starting with the front bumper back to the windshield pillars is the front section.

As an estimator it’s important to know the names of these parts. Let’s take brief look at these parts starting with the sheet metal or plastic parts that cover the structural. Starting at the front we have the bumper cover or front bumper, right and left front fenders, hood, and some vehicles may have header panel and/or cowl vent panel. Now looking underneath the outer panels we have some of the major structural parts. Front bumper reinforcements, radiator support which may consist of several parts welded together, fender aprons, this is what the fenders bolt on to. The front side member rails, cowl area, which may be referred to the firewall area. A pillars, this is the pillars the windshield sets in. By the way, the windshield is a structural part as it helps hold the structure together. Therefore, from a pillars all the way to the front bumper cover is the front section of the vehicle.

Frame Types

All of the frames on modern vehicles are designed with crush zones, but there are different types of frames.

Body over frame consists of a frame and a body. With the body or body parts removed the motor and suspension are still attached to the frame. While the early model were not designed with crush zones, they were a body over frame type.

Unibody

Space