These lessons are now open to help collision repair students learn from home. I am lifting the Patron fee to access this content during this time, as many schools are closed. However, I do appreciate your support and hope my Patrons continue to support this website and training.

If you would like to help and support this website, then I would greatly appreciate it. For more information visit. www.Patreon.com/CarAddictGarage

LESSON 1 – LESSON 2 – LESSON 3 – LESSON 4 – LESSON 5 – LESSON 6 – LESSON 7 – LESSON 8 – LESSON 9 – LESSON 10

Welcome to Auto Repair Estimating. These lessons are designed to provide you with the basics to Auto Estimating. I hope you enjoy the lesson. Donnie

Lesson 7 – Calculating the Labor and Material Costs

“Nothing is particular hard if you divide it into small jobs.” ~Henry Ford

What This Chapter Covers:

This chapter covers how to deduct for paint overlap and how to calculate the different labor operations and material cost.

Why This Is Important:

An estimator must know how to calculate labor times and material costs and add not included materials with a total amount to provide the customer with a complete repair estimate.

Topics Covered In This Chapter Include:

• Deducting For Paint Overlap

• Adding For Clear Coat

• Adding For Tri-Coat

• Adding For Two-Tone

• Calculating Materials Cost

• Adding Not Included Materials Cost

This chapter has been aligned with the following 2013 NATEF/ASE tasks:

•B:18 Recognize and apply overlap deductions, included operations, and additions. HP-I

•B:19 Determine additional material and charges. HP-G

•B:20 Determine refinishing material and charges. HP-I

•B:20 Apply math skills to establish charges and totals. HP-I

In the Mitchell estimating guides, refinish labor time, R&I time, and O/H time are usually right under the title of each part. The R&R time is usually listed with the part.

All paint times given in the guide are for painting one panel at a time. Many times, however, we paint more than one part at a time. For example, if a car was hit in the front, it may damage the hood and both front fenders. Therefore, three parts would be painted at the same time.

Would it take the same amount of time to do all three panels at the same time as opposed to pulling the car in and out of the booth three separate times to paint each panel separately? Of course it would save time to paint them all at once. You would only mask once, mix paint once, spray the paint once, and clean your spray gun once. We should deduct part of the time when painting more than one panel.

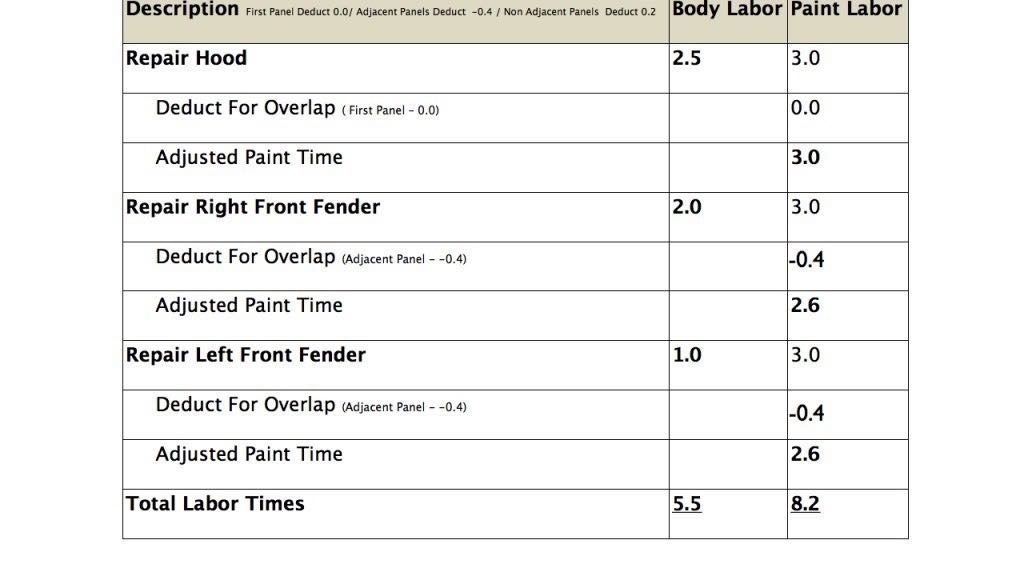

The first major panel will not have any deduction for overlap, but for each additional major adjacent panel, the estimator needs to deduct .4. If it is not an adjacent major panel, the estimator will need to deduct .2.

In the example above, we have a hood and two fenders. Let’s say the guide gives 3.0 paint labor time for each panel. With no deductions, you have a total of 9.0 refinish hours. That would not be correct because we did not deduct for overlap. An adjustment to the time will need to be made.

The first major panel is the hood, which gives us 3.0 hours. The next major adjacent panel is the fender, which gives us 3.0 hours. Since this is an adjacent major panel, we will deduct .4, giving us 2.6 hours. The next major adjacent panel is the other fender, which gives us 3.0 hours. We will deduct .4 from that time as well, giving us 2.6 hours. The total paint time will now be 3.0+2.6+2.6 = 8.2. This is .8 less time that we will charge after deducting overlap. Remember that panels not adjacent to the panel you’re painting will only have .2 deducted per panel.

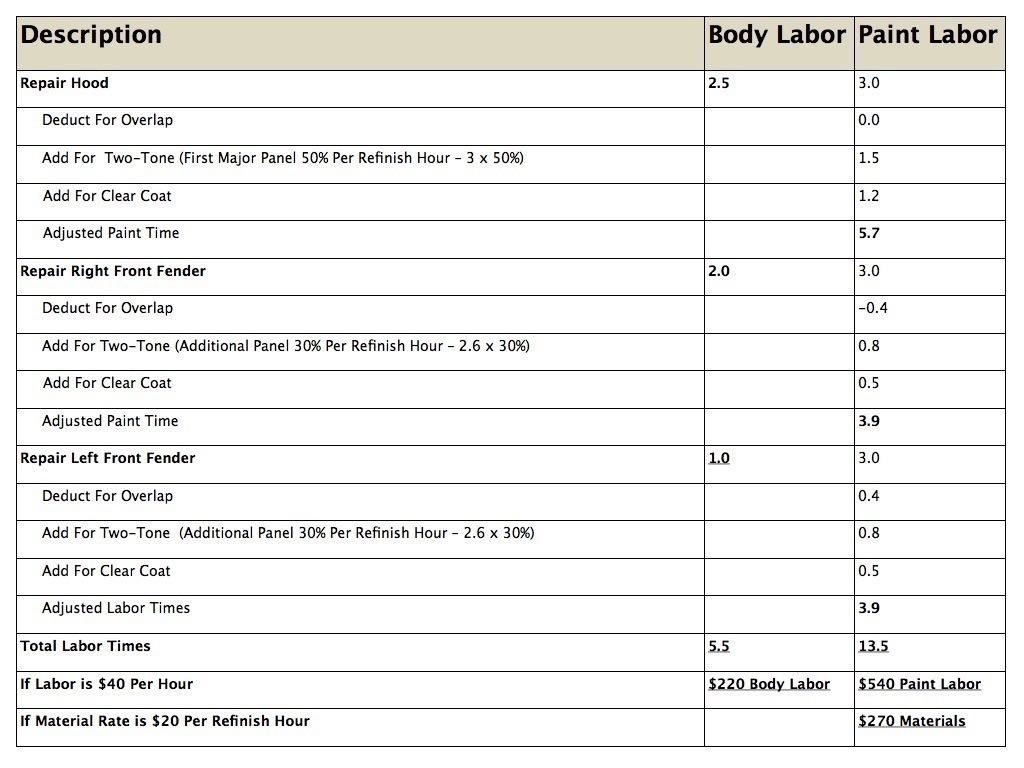

Here is an example of how this works on an estimate.

Click On Example To Enlarge

Major Panels

Deducting for paint overlap should only be applied to major panels. Major panels include the following:

• FRONT PANEL

• FRONT SHEET METAL

• FENDER

• FENDER AND RADIATOR SUPPORT

• HOOD

• ROCKER

• ROCKER AND CENTER PILLAR

• DOOR

• DOORS AND CENTER PILLAR

• DOORS/CENTER PILLAR AND ROCKER

• DOORS/CENTER PILLAR/ROCKER AND QUARTER

• ROOF

• ROOF AND BACK PANEL

• BACK AND CORNER SIDE PANELS CAB ASSEMBLY

• REAR SECTION

• REAR SECTION AND ROOF QUARTER AND BACK PANEL QUARTER AND ROCKER PANEL QUARTER PANEL

• PICKUP BED PICKUP BED SIDE VAN SIDE PANEL LUGGAGE LID LIFTGATE OR TAILGATE

When writing auto repair estimates, the auto estimator must add for clear coat. The clear coat takes time to spray on the vehicle, and it takes more paint materials. Therefore, there should be a charge for the time that it takes to mix and apply the clear coat and a charge for the cost of materials used.

The time should be added to the refinish labor category to cover both labor time and material charge. We will discuss how to determine the material charge below.

You may be thinking that most vehicles have clear coat; why doesn’t the guide include the time it takes to clear coat? Not all cars have clear coat, and you should not get paid for an operation that you did not perform. I think it is fair for technicians to get paid for everything that they do, but if we start charging for things that we don’t do, fraud results and can lead to a lot of trouble. So if you’re going to add for clear coat or any other not included operations, make sure it needs it.

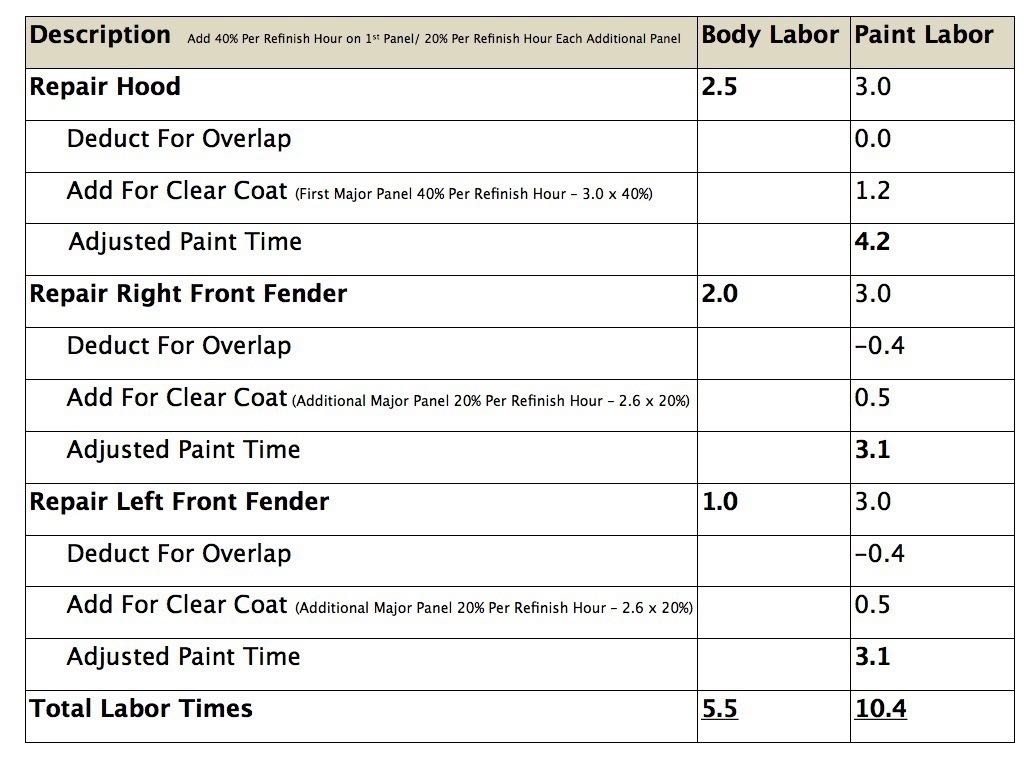

If you clear one panel, you will need to mix your clear, tack the surface that you’re spraying, spray the clear on the panel, and clean your spray gun. To calculate time for clear coat, you add 40% per refinish hour of the time given to paint the panel. If you’re spraying a panel with 3.0 hours, you would multiply 3.0 x 40% = 1.2. So to paint and clear this panel you have 3.0 + 1.2 = 4.2 total paint time.

For each additional panel, you will need to deduct for overlap and then add 20% for clear coat. For example, if the adjacent panel gives 3.0 hours, we will deduct .4 to give us 2.6. Now multiply 2.6 x 20% = .5. Add 2.6 + clear time of .5 to get a total of 3.1 paint time to paint and clear the adjacent panel. This same formula will apply to each additional panel. Deduct overlap and multiply by 20%. There is a maximum clear coat time of 2.5. Once the clear coat time reaches 2.5 hours, this is the full amount allowed to charge for clear coat. With the exception of a complete paint job, I can’t find it in the P-Pages, but I always charged 4.0 hours to clear coat a complete vehicle.

Let’s take a look at the previous example but with adding clear coat.

Click On Example To Enlarge

Adding for tri-coat or three-stage paint is similar to adding for clear coat. Tri-coat consists of base coat, mid-coat, and clear coat, which are three different operations that you must do to get the paint to match properly. The mid-coat may be a pearl coat or a tinted clear to create different effects, including shifting colors and adding more depth.

It may be very difficult to determine by looking at a paint color if it is a tri-coat or not. To be certain you are charging for the correct operation, locate the paint code on the vehicle and look it up.

The estimating guide will give you some general ideas of where these paint code labels may be located and will help you identify tri-coat colors.

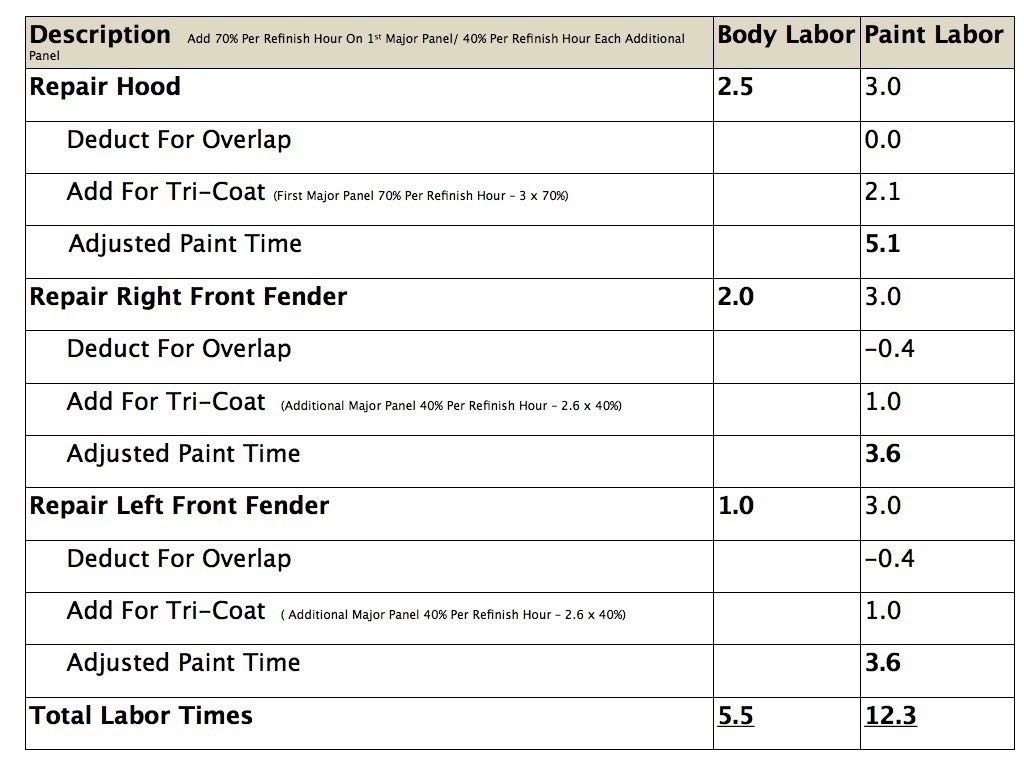

When adding for tri-coat, you do not add for clear coat. The clear coat time is included in the tri-coat application. Use the same formula by deducting for overlap and for calculating clear coat, except use 70% per refinish hour to your first panel and 40% per refinish hour to each additional panel.

To calculate time for tri-coat, you add 70% per refinish hour of the time given to paint the panel. If you’re spraying a panel with 3.0 hours, you would multiply 3.0 x 70% = 2.1. So to apply base coat, mid-coat, and clear coat this panel, you have 3.0 + 2.1 = 5.1 total paint time.

For each additional panel, you will need to deduct for overlap and then add 40% per refinish hour for tri-coat. For example, if the adjacent panel gives 3.0 hours, we will deduct .4 per panel to give us 2.6. Now multiply 2.6 x 40% = 1.0. Add 2.6 + tri-coat time of 1.0 to get a total of 3.6 paint time to apply tri-coat to the adjacent panel. This same formula will apply to each additional panel. Deduct overlap and multiply by 40% per refinish hour.

Let’s examine the same example that we’ve been discussing with tri-coat.

Click On Example To Enlarge

Two-tones are not included in the time given to refinish a panel. Two-tone means there are two different colors on the vehicle. This does not include custom paint jobs or stripes. Time for many of those operations will be a judgment time at the estimator’s discretion and expertise.

For two-tones, another simple formula is used to determine the time to estimate for this operation.

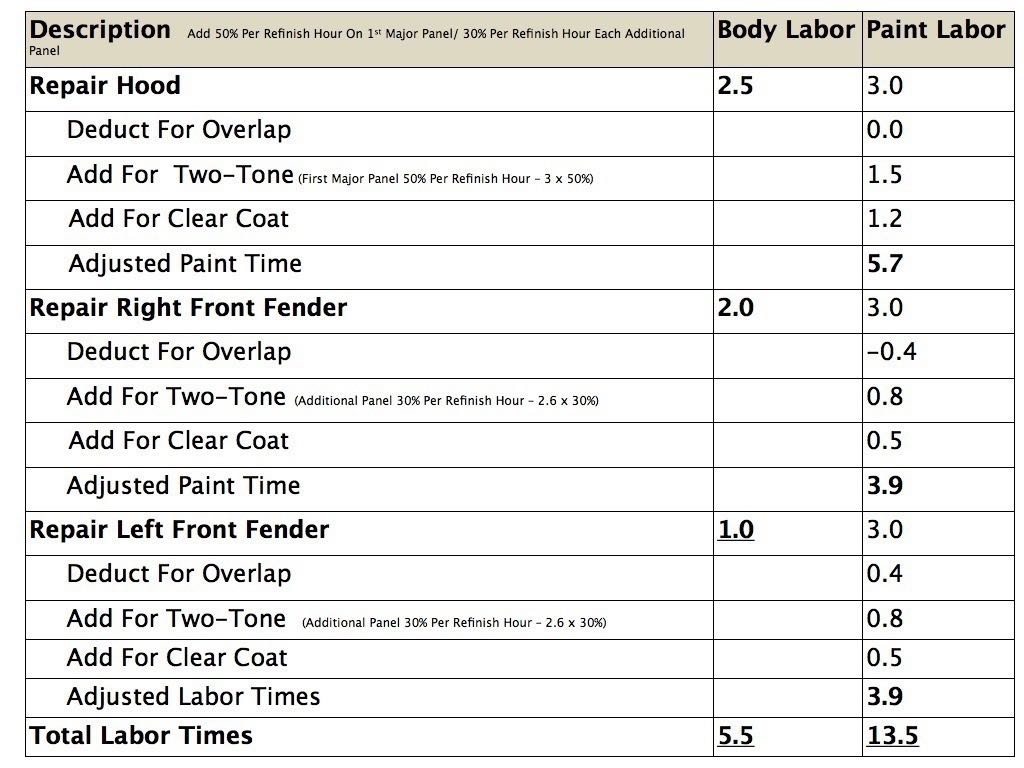

To calculate two-tone, add 50% per refinish hour for your first major panel and 30% per refinish hour for each additional panel. Basically, it is the same formula as clear coat, just different numbers to plug in. However, this two-tone calculation does not add the clear coat. It is possible to have a single-stage, two-tone paint job, so clear is not figured into the two-tone time.

If the first panel gives 3.0 to refinish the panel, there is no overlap deduction on the first panel. Multiply 3.0 x 50% = 1.5. If the part is base coat/clear coat, then add for clear coat by multiplying 3.0 x 40% = 1.2. Now you have 3.0 + 1.5 (two-tone) +1.2 (clear) for a total of 5.7 hours of paint time.

If the second panel gives 3.0 to refinish the panel, deduct .4 for overlap. 3.0 – .4 = 2.6. Calculate two-tone by multiplying 2.6 x 30% =.8. Next, calculate clear by multiplying 2.6 x 20% = .5. Now you have 2.6 + .8 (two-tone) +.5 (clear) for a total of 3.9 hours of paint time.

Let’s take a look at the same example that we’ve been working on and determine what the refinish time will be with two-tone added.

Click On Example To Enlarge

Add For Edging and Underside

I am going to cover edging, spraying underside, and blending, but I am not going to provide an example or include it in the material charge example. Adding for these refinish operations is straightforward. No deduction for paint overlap is taken for these refinish operations.

Time is provided to edge or paint the underside of parts. In all of our examples, we only repaired the parts. Normally, when you repair a part, the jamb or inside of the panel does not need to be repainted. However, anytime you replace the part, it will be necessary to paint the edge or underside.

For example, if we replace a right front fender and it pays 3.0, that does not include edging the jambs of the fender. All you need to do is look in the estimating guide and it will give you the time for edging or to paint the underside of the panel. The right front fender may state to add .5 for edging. This would give you a total paint time of 3.5 to paint the right front fender.

There is no overlap deductions for edging or spraying the underside, but the clear coat, tri-coat, or two-tone formulas still apply.

Many new cars have different color schemes for the insides of the panels. Therefore, you should be able to add for two-tone if this is the case.

Blending

Blending is the process of blending clear coat into an adjacent panel and clear coating the whole panel. To calculate blend time, use the paint time given in the estimating guide and divide the number by 2 or multiply the refinish hours by 50%. For example, let’s say the job we’ve been working on needs the front door to be blended into. To keep it simple, we’ll say the door refinish time given in the estimating guide is 3.0 hours. No overlap deductions are taken with blend time. Take the 3.0 hours and multiply it by 50% for a total of 1.5 refinish hours. 3.0 x 50% = 1.5. A total of 1.5 hours will be added to the refinish labor on the estimate.

1. Traditional Materials Charge

The amount to charge for paint materials is determined by our refinish labor hours. The estimator calculates the total number of refinish labor hours and multiplies by a determined number. We used to multiply it by 50% of the refinish labor, but with the increased material costs, the number is usually higher now. In this example, we’ll use 50%, but the number will be determined by the repair shop. If the refinish labor is $40 per hour, the charge for materials will be $20 per refinish if following the 50% calculation.

If you charged 3.0 hours to paint a fender and the materials charge rate is $20.00, then the material charge will be $60 for paint materials.

What Is Not Calculated

What this method does not pay for is any adhesives, fillers, clips, etc., that you may use. With the price of these materials, you can lose money if you’re not careful. Be certain to add the materials that are not included in the refinish labor time. More information about not included materials will be covered later in this chapter.

Charging For Materials From The Refinish Time

Let’s take a look at the two-tone example that we’ve been working on and determine what the charge for materials will be. We’re going to use $40 for the labor rate and $20 for the materials.

This method of calculating material charges is the method that has been used for many years and still is today. Computer estimating systems, such as CCC One, will use this calculation and calculate the charge for materials.

Click On Example To Enlarge

13.5 is the refinish time

13.5 x $20 = $270 (if the material rate is $20 Per Refinish Hour)

The material charge for this job would be $270.00

The refinish materials charge figured by the refinish hour does not include many of the supplies used to repair a vehicle. These materials may be required to properly repair the vehicle to pre-accident condition. If the estimator overlooks or fails to add these materials to the estimate, then the repair shop will not be paid for the materials used. Be certain to itemize the materials on the estimate. Do not add a line for additional materials and add one lump sum.

The customer or insurance company will not understand what the lump sum charge represents and may complain when agreeing to pay for it.

Below are some suggested materials a shop may use that should be added to the estimate.

• Grinding discs

• Dent Repair Supplies (studs for pulling, etc.)

• Body Filler

• Glaze Putty

• Sandpaper For Feather Edging Damaged Area

• Primer Surfacer

• Guide Coat For Block Sanding Primer Surfacer

• Sandpaper For Block Sanding Primer Surfacer

• Adhesives

• Crash Wrap

• Plastic or Masking Material For Covering Car

• Textured Coatings

• Buff and Polishing Supplies

• Detailing Supplies

• Coolant Fluid

• Transmission Fluid

• Power Steering Fluid

• Flex Additives

• Adhesion Promoters

• Seam Sealer

• Sound Deadener Material

• Gravel Guard

• Double-Sided Tape

• Anticorrosion Materials

• Undercoatings

Some shops are experiencing a loss in materials and have moved away from charging materials by the refinish hour method. Instead, they are using an itemized system that lists each item they use, from the number of ounces of paint to the number of razor blades. This method is going to take more time, but systems like http://www.pmclogic.com/ are available to help make this easier.

[…] 1 – LESSON 2 – LESSON 3 – LESSON 4 – LESSON 5 – LESSON 6 – LESSON 7 – LESSON 8 – LESSON 9 – LESSON […]