These lessons are now open to help collision repair students learn from home. I am lifting the Patron fee to access this content during this time, as many schools are closed. However, I do appreciate your support and hope my Patrons continue to support this website and training.

If you would like to help and support this website, then I would greatly appreciate it. For more information visit. www.Patreon.com/CarAddictGarage

Click Button Below For Lesson

I hope you enjoy this training module. Let me know if you have any questions, or suggestions you may have to make this training module a better learning experience for you. Donnie

Lesson 8 – Paint Prep

Lesson 8 – Paint Prep

It’s All About Prep

“It’s better to look ahead and prepare than to look back and regret.” ~Jackie Joyner Kersee

In this lesson we are going to cover how to properly prep a car. This is where much of the hard work is at, but perhaps the most important steps of producing a professional quality paint job.

This page is the full lesson, which includes text content, videos and resources. I also broke it down to only the videos and resources. Just click the button below if you prefer to view only the videos or resources. Note: some browsers and mobile devices may not play videos below…but they should work on the videos page. If you are still having problems viewing videos, then you can watch the playlist on YouTube.

Video Overview

This instructional video is an overview of prepping a car. We also have more demonstration videos below in this lesson.

Paint Prep

One of the most important things, or perhaps the most important thing, you need to do when painting a car is to properly prep it. Without proper preparation, the rest is useless. It’s like an iceberg…you see about 10% to 20% of it sticking out of the water. However, what you don’t see is the other 80% to 90% that is underneath the water. Well, in painting, we see the paint, the finished product. However, 80% + of that awesome paint job is due to what you can’t see, the hours of prep.

It is a common mistake to rush through the prep step, and then try your hardest to paint like a pro. However, that just does not work. It’s just like trying your hardest on a test that you did not study for. No matter how hard you try on test day, you’re not going to do well without learning the information first.

In this book, we are going to focus on cleaning… That must be important as I keep bringing it up. I hope to have this etched into your mind by the end of this e-book. We’re also going to focus on featheredging, block sanding, final sanding, and once again, cleaning before putting it in the paint booth.

The Professional Paint Job Is Not About A Fancy Paint Gun

All the awesome auto paint colors are what make cars look great and attract interest from car enthusiasts around the world. Ed Roth broke the mold in the 1960‘s by altering the stock look with modified body parts, pinstripes, and custom paint. Since then people began customizing cars in every way imaginable. This has created a lot of people’s interest in custom painting. However, the same rule applied then and still applies today, which is, it does not start with the paint gun, it starts with the wash mitt.

As a collision repair instructor, I see the same thing many times when it comes to painting a car. Students tend to rush through the preparation stage and then expect superior end results. Painting is an art and it does take practice. Travel speed, distance, spray pattern overlap, and technique is necessary to learn to produce professional results, but more attention needs to be concentrated on preparing the car for paint than the spraying itself.

Here is an example that I give my students when I am trying to convey this point. Let’s say that we did not properly wash and clean the vehicle. Then we sanded the car, but fast and sloppy. Lastly, we slap a little tape and paper to mask it off. If Chip Foose (very known for his painting abilities) came in and painted the car, how would it turn out? Well, it would have dirt in it as we rushed through the preparation process, probably fish eyes in the paint, paint overspray on the glass and moldings where paint seeped through. Well, I guess you could say it would look horrible. The paint would probably peel later due to a loss of adhesion. All of Foose’s abilities are useless if the car is not prepped correctly. This is similar to spending $200,000 building a nice home on top of a bad foundation. Even if you use the best materials to build the house, it will fall apart if the foundation is not right. Therefore, assuring that you have a good foundation is important before building a home, just like having a properly prepped car before painting it.

I know that I stress that point, but it is often overlooked. So get your wash mitt out and spend extra time washing the car before starting repairs. Then take your time and ensure that all the surface to be painted is sanded so the top coating will properly adhere. Always re-clean the area to remove all dirt. Dirt in crevices may blow out with the air pressure of the paint gun and get in the paint job, if you do not blow the car off thoroughly before masking it off. Use a good quality paper and masking tape to protect glass and the other items that you do not want painted. Wipe the surface with quality wax and grease remover to remove all traces of contaminations, waxes, silicones, etc. Use a tack rag to remove final dirt and lint before applying the paint coatings. Now you can start spraying the car. Spend 80% of your time and efforts becoming a good prepper and 20% of your time perfecting your spraying techniques. This is what it takes to produce a professional paint job that will look great and turn heads.

Featheredging

After the body work has been completed and finished with 150 grit sandpaper, many shops send it from the body shop to the paint shop. However, there are many variations of how shop owners like to divide this, but traditionally, after being blocked with 150, it’s sent to the painter.

We finish our body work in 150 grit. However, this may very from shop to shop. Depending on preference, the body work may be finished with anywhere from 150 to 220 grit sandpaper before applying primer.

The first thing a painter will need to do before priming and painting is to prep the repair area. The block left 150 grit scratches on the filler and surrounding area. There may also be grinding marks, and edges where the paint coatings meet the metal. To smooth the paint edges out and the other scratches, you will need to featheredge. This is done using a dual action sander with 220 grit sandpaper. This is the one and only exception when you can tilt the DA on its edge. This will help you make the transition from paint to metal easier. You want to bevel each layer of paint or primer at least 1⁄4 inch so it will look like you have rings around your repair area. Each ring should vary from 1⁄4” +. If this is not properly done, the rings may show up after the car has been painted.

Featheredging Video Demonstration

Sanding

Now that the featheredging is completed, we can sand everything else that is going to be painted. But why do we sand? Many people think it’s to provide a smooth surface, but it’s actually the opposite. We are actually roughing the surface up so the paint will stick. Think about painting a piece of glass. It is pretty easy to imagine the paint peeling off as the glass is so smooth. End result…sanding provides adhesion to prevent peeling.

How To Prep A Panel Video Tutorial

Mechanical Adhesion

Primer and/or paint will not adhere to an un-sanded panel. The surface must be roughed up, which will produce a mechanical adhesion. Not properly preparing the surface will result in loss of adhesion and peeling. Most paint starts peeling from an edge, so make certain special attention to edges is taken.

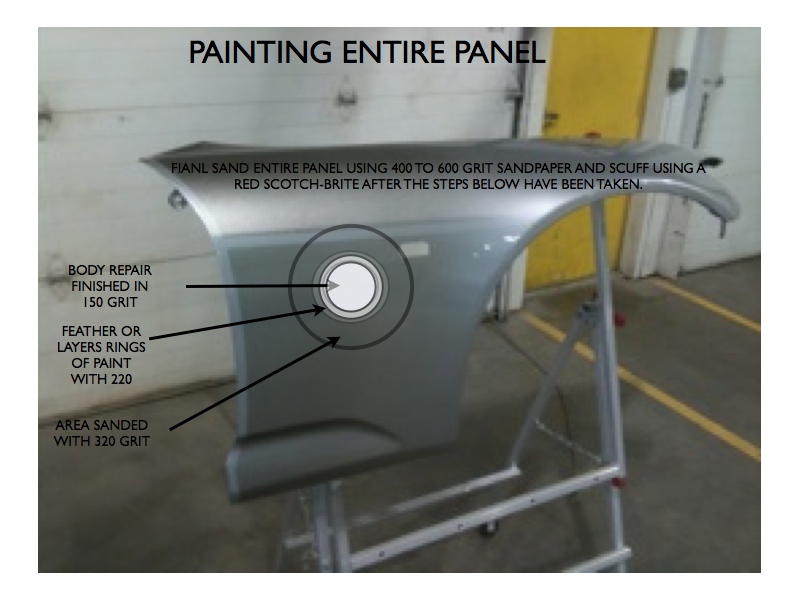

When Painting The Entire Panel

Before you start priming and masking prepare the entire panel for paint or clear coat. First, sand several inches around the repair area with 320 grit on a DA sander. (This is the featheredge area we just discussed.) If the entire panel is going to be painted, go ahead and sand the entire panel with 500 grit on a DA sander. (You can also hand sand.) Make certain that when final sanding with a DA that you use the interface pad. Once the panel is sanded with a DA sander or by hand with 400 to 500 grit, use a red scuff pad to scuff the edges and all other areas that are hard to get with a DA sander. Do not rush this step, as edges are very important. If paint or primer is going to peel, it usually starts from an edge. Once you have the panel completely sanded, clean the surface with compressed air and wipe the panel with wax and grease remover. Go ahead and clean surrounding areas where tape may be applied to ensure the tape will adhere properly.

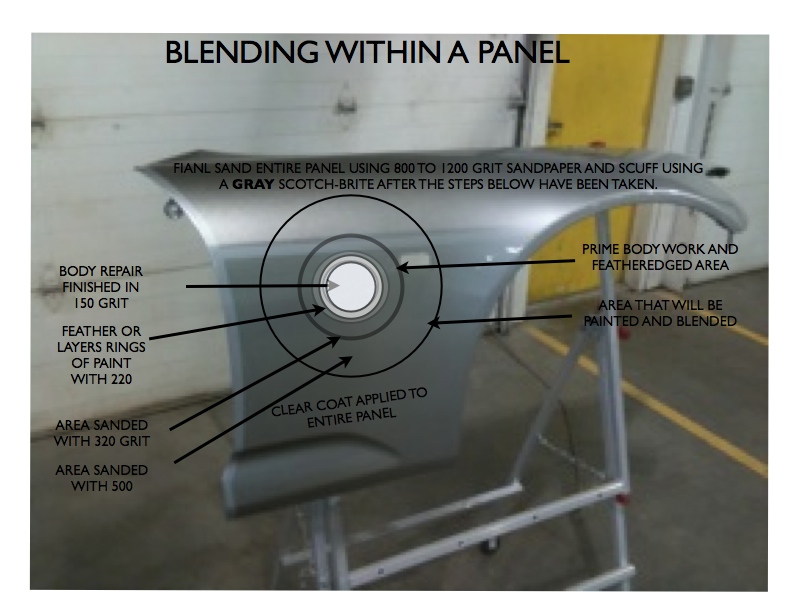

Blending Within A Panel

What if you’re blending within a panel? Blending within a panel is where you are only going to paint the repair area and not the entire panel. This still requires sanding to the entire panel, as the entire panel will need to be clear coated. This uses the same methods, but you must use finer grit sandpapers. Now I just want to give you a heads-up on how to do this, but do not get stressed about blending. We’ll cover that later.

To repair a blend within a panel for primer, sand past the repair area with 320 grit using a DA with an interface pad. Sand several inches past your repair area. Then switch to 500 grit DA using the interface pad and sand an additional 2-4 inches past the repair area. Now switch to 800 grit sandpaper using a DA with interface pad to sand the remaining panel surface. Once the entire panel is sanded, use a gray—make sure it is gray, not red—scuff pad to scuff the edges and hard-to-reach areas of the panel. Now you’re ready to clean the surface as explained above. Blow with compressed air and wipe with wax and grease remover.

Eliminate Peeling

By sanding the entire panel before priming, you will ensure that all primer will adhere properly. If your primer sprays out a little further than you intended, you will be safe, as it has already been sanded. I have seen primer applied over un-sanded paint before. If left like this, it will cause the primer and whatever is applied over the primer (paint and clear) to peel off with it. That is something that you definitely do not want to happen. Now that the panel is repaired and prepped, you can get it ready to mask and prime.

Masking

The repair area has been repaired and finish sanded with 150 grit sandpaper, featheredged and the panel prepped for primer. Now it is time to get some primer on the repair area.

Masking Before Priming – No Hard Edges

Once the body filler or glaze putty is block sanded with 150 grit and featheredged with 220 and the panel is final sanded and prepped for paint, now we are ready for primer. The first thing that you need to do is mask the adjacent panels and areas that you do not want to get primer to get on. This sounds simple enough, but many mistakes are made doing this. One of the common mistakes is making hard edges with the primer. This is done by masking a square around the damaged area. During the priming process, primer is sprayed against the tape edge causing a hard edge. This creates additional work trying to feather the primer edge smooth.

How To Mask Before Priming Video Tutorial

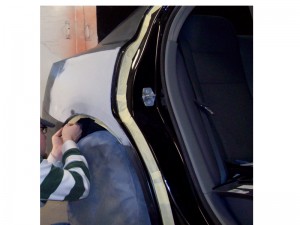

In the photo above, you can see where am imitating how a square is masked around the damage when primed. This causes more work when block sanding the primer surfacer. There have been times when the primer lines were sanded completely out when sanding, but were slightly visible after the paint job was complete. Save yourself time, energy and the possibility of this paint defect by not making this mistake.

Video Demonstrating How To Make For Primer

Take Time To Save Time

The purpose of masking is to prevent primer overspray from getting on the areas that it is not intended to be. With the types of primers used today, it is necessary to take all measures to make certain that overspray does not get onto the unintended surfaces. First, the two-part epoxy and urethane primers are very difficult to remove. Back when we used to use lacquer primer, all the overspray could be cleaned with a little thinner on a rag. However, today’s catalyzed primers do not wipe off that easily. The second reason is that these primers carry a long distance. Again, with the old lacquer primer, if it traveled more than 12 inches it would be dust by the time it landed on the surface. However, the primers of today can travel the full length of the vehicle and still stick to the painted surface, glass, moldings, etc. With this said, more care should be taken to properly mask a vehicle for primer. The extra time spent properly masking a repair area for primer will save you much time rubbing, sanding and buffing to remove unnecessary overspray.

No More, No Less

You need to be certain to primer everything that needs to be primed. That is any metal, filler or scratches made by the 150 – 220 grit sanding. However, there is no need to prime anything else. For example, if you have a 6″ diameter repair area, there is no need to primer the entire or even half of the panel. This is something that I have noticed some students tend to do. You only need to prime the repaired area. The spray will slightly exceed the repair area, but try to keep it small as possible. Another thing to remember is to keep primer out of areas that it does not need to be. For example, molding edges and jambs. There is nothing sloppier than to open a car door after it has been completed and see primer overspray, or see primer on the edge of a molding. The reason this happens is because many times when masking for primer, the person masking thinks, well, this is just for priming and rushes through the masking process. Then when masking to paint, more care and attention to detail is taken. You may not have paint on the unwanted areas, but you have primer, which looks even worse than the paint would have. So be certain to take as much pride in masking the vehicle for priming as you do for getting it ready for paint.

When masking off jambs, mask to the edge of the panel. There is no need to allow any primer to wrap into the jamb area. Therefore the edge of your tape should be at the edge of the panel to prevent overspray from getting into the jamb area. Now when we mask for painting, we will mask back from the edge slightly to allow a little overspray to spray onto the jamb. This eliminates noticeable lines, but for now, mask right on the edge of the panel.

Nothing Hard About It – How To Eliminate Hard Edges

The only hard edges you should have when priming are the jamb edges. You should try to avoid all other edges if possible. Hard edges are a definite “no-no.” Let’s take the same 6 inch diameter repair area and mask an 8 inch square around it. You only get primer where you want it, but now you have hard edges to featheredge out. Let’s look at another approach to mask the 6 inch repair area. Mask all adjacent panels and anything near the repair area that you do not want primer on. Then you can go out 12″ and back mask if needed. Back masking is the process of masking something and flipping the paper over, creating a smoother edge. When correct, the paper will now have the bottom side of the paper facing up. For instance, if the top of the paper is blue and the bottom of the paper is white, now the white will be showing. Now that we have it back masked, we still do not need to spray primer all the way to the paper. Try to avoid that if possible. Ideally, try not to have any edges at all. The overspray makes an easy area to sand with as little effort as possible.

If In Doubt…Cover It

Overspray is something that you do not want to get on unwanted surfaces. So must the entire car be covered? The answer is, if in doubt cover it. It only takes a few minutes to unroll plastic and cover the car. If we take the 6 inch diameter repair area and mask around it using 18 inch paper and set the spray gun using low pressure, you may be all right. However, just a little overspray can cause you hours of cleanup and grief. This is something that you need to get a feel for, but if in doubt, bag the car with plastic. If you’re priming the entire panel, be certain to cover the entire car with plastic. A little time spent in the front end will save much time in the back end.

Tell-Tale Signs

Masking is perceived by amateurs as being unskilled and unimportant. However, I think you will agree that the best looking paint job can look horrible if you see paint and/or primer on moldings or in jambs. The idea is to make invisible repairs. Improper masking is the easiest and fastest way to determine that a vehicle has been repainted.

We’re masked and ready to prime. So let’s discuss primers.

Priming the Repair Area – Why Prime and What Types of Primer to Use

What Is Primer?

According to Wikipedia, “primer is a preparatory coating put on materials before painting. Priming ensures better adhesion of paint to the surface, increases paint durability, and provides additional protection for the material being painted. The term primer comes from the Latin word primus meaning first because it precedes the other coatings.”

Adhesion Is Key, But There is More

Adhesion is a key reason to use primer. However, in automotive primers, it also provides corrosion protection too. Therefore, a primer that provides both good adhesion and corrosion protection is needed. I recommend using an epoxy primer to provide these needs. Most epoxies can be applied on most types of substrates and is compatible with most top coats. Some technicians prefer etch primer to apply on bare metal to provide good adhesion. Etch primer has a high acid content that bites into the metal, but does not have the corrosion protection like epoxy does. I will talk about when etching primer in an aerosol can come in handy in a little bit.

Mixing Epoxy – It’s Like The First Day Of Class

We use PPG and Shopline (a line of PPG) products, but other brands may have similar directions. Be sure to read the manufacturer’s procedure page to determine what they recommend. However, many epoxies have an induction time. This is an amount of time the two chemicals need to be mixed together before using. It’s like going to a new town or your first day of class. You’re quiet and nervous until you get to know the people around you. Once you get to know everyone, you feel much more comfortable. After mixing the catalyst with the epoxy primer, the chemical needs a little time to accept each other as well. It may only be 15 to 20 minutes, but be sure to read the procedure page for the specific product to know for sure.

Mixing Epoxy Primer Video Tutorial

Spraying The Primer

According to the new 6H rule, all primer needs to be sprayed inside an approved spray area if spraying more than 3 oz. If you’re priming a small area, you may consider lowering the fluid, narrowing the fan pattern and turning the air pressure down. This will allow you to spray a smaller area with less overspray. Be certain to cover all areas that were sanded with 220 grit or coarser. Apply two medium wet coats to the repair area. Remember not to spray primer all the way to your masking paper. Keeping the primer area as small as possible will provide the easiest repair.

Additional Note: Epoxy primer is my preferred primer for superior epoxy primer. However some technicians prefer self etch primer. This is a single stage primer that contains acid, which etches to the metal. Either primer, epoxy or self etch primer can be used on bare metal.

Watch How To Spray Epoxy Video Below

Flash Time – Don’t Even Think About Passing Go

Flash time is the amount of time that is needed between coats. Rushing the flash time throughout the car refinish process is something I see often, which results in many different problems. Each coat must have time to flash to allow all the solvents to evaporate. If you apply another coat before the primer has flashed off, it will trap the solvent and cause a number of problems. Loss of adhesion and solvent popping are a few of the most common problems. You must also realize that the time given in the procedure page is probably for a temperature of around 70 degrees. If it is 50 degrees in the shop at the time you spray the primer, then flash time must be extended. One coat at a time. No double coats or rushing the flash times. You’ve spent a lot of time on the repair; don’t blow it now.

Primer Surfacer – The Final Fill

The Purpose

Primer surfacer is the final step or your final chance to produce the perfect surface with the correct texture before painting. Scratches and small imperfections can be repaired with this fill primer. Filling is the main purpose of this type of primer: you can think of it as final filler. We finished the body filler or glazing putty with 150 grit, featheredged, cleaned the surface, masked, applied two coats of epoxy, and now we’re ready to apply primer surfacer.

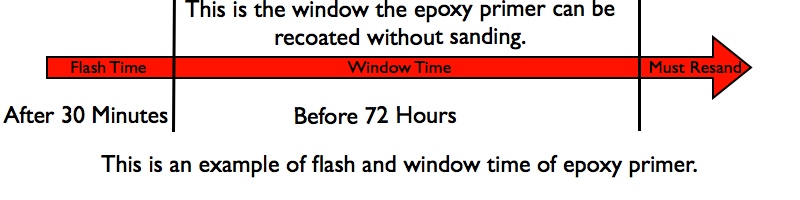

Flash and Window Times

After the epoxy has been applied, you can now apply the primer surfacer. Be certain to allow the epoxy to flash the recommended amount of time. The manufacturer’s procedure page or technical data sheet will tell you how long of a flash time needed before top coating. With PPG you need to let it flash at least 30 minutes. However, you also have a window. This is the time that you have to apply another coat without sanding. Most epoxies have a long window time. The epoxy that I am familiar with has a 72 hour window. If you wait more than 72 hours to apply the primer surfacer, it must be lightly scuffed to ensure proper adhesion.

Adhesion – Mechanical vs. Chemical

I keep talking about adhesion. I would like to expand on this and tell you why this is important. Adhesion is just another word for stick-to. For instance, in upcoming lessons we will refer to glue as adhesives. To prevent body filler, primer, paint, etc., from peeling it needs to adhere to the surface. There are two ways to provide adhesion. The first is a mechanical adhesion. This is why we sand the surface before we apply the coating. That is why it is so important to sand the edges extremely well. If a panel is going to peel, chances are it will start peeling from an edge. The second type of adhesion is chemical adhesion. This is when there is still a chemical bond with two products. For example, the 72 hour window with the epoxy primer is the time the surface will produce the chemical bond. After that, the chemical bond will no longer adhere. That is why after the 72 hour window, the surface will need to be re-sanded. Since we no longer have the chemical adhesion, we now have the mechanical adhesion to take its place.

Applying The Primer Surfacer

All right, I took a little rabbit trail, but I wanted to make sure that you understand flash times, window times and the types of adhesion. Now, let’s talk about applying the primer surfacer. After the epoxy has flashed off the recommended amount of time, apply your first coat of primer surfacer. Only apply enough to cover the epoxy primer. Check the procedure page to determine the recommended number of coats needed to achieve the desired thickness or mils. Normally, two to three coats are sufficient. I usually apply two wet coats allowing each coat to flash off. Apply each additional coat a few inches past the first coat.

How To Mix and Apply Primer Surfacer Video Below

What’s Next?

We’ve applied epoxy primer to provide additional adhesion and corrosion protection. Then we applied primer surfacer to fill the minor scratches and small imperfections. Now we’re ready to apply guide coat and block sand the primer.

Block Sanding Primer

The car has already been prepped for priming, masked and sprayed. Now we need to allow the primer surfacer to dry. First let me clear something up so there is no confusion. Some technicians call primer surfacer, primer filler. This is because it is designed to fill small scratches and other imperfections. However, it is the same thing. Another thing to remember about this type of primer is that it must be block sanded.

What You See Is What You Get

Block sanding is performed to level the surface. All lows, scratches or any other minor imperfections must be completely removed. If you leave a small chip or scratch it will show up in the paint job. In fact, sometimes the glossy clear coat will magnify the imperfection. That is why I say in the title, what you see is what you get. If you can see it in the primer, you will definitely see it in the paint.

Some Steps Cannot Be Rushed

You’re almost done, it’s primed, now all that you have to do is block it and get it in the booth to paint. It’s tempting to rush the drying time, but not allowing the primer surfacer to fully dry is a common mistake made by students. This can cause problems for you. Primer may feel dry to the touch, but it may still have solvents evaporating. As solvents evaporate, the primer shrinks. Therefore if you rush the sanding process, you may have it perfectly sanded. However, after the solvents evaporate the primer shrinks and may actually suck up into the scratches that it was sprayed over. This is called sand scratch swelling. And I have even seen it happen after the car has been painted. To eliminate this be sure to wait the recommended dry time according to the primer p-pages. Every product and paint company is going to be different so read the p-page for the specific primer that you are using.

Is Bigger Better?

This is true in this case. The bigger the block the better results you will get. Use a block that fits the panel contour and use one that is big, but fits the area. You can think of blocking like leveling. If you were going to level the ground, would you want to use a tractor with a narrow blade that covered about 4 ft. or would you use a blade that covered 10 ft.? Well, of course you would want to use the biggest one, but if you were only leveling a 4 ft. wide strip for a sidewalk, the smaller blade would do a better job. The 10 ft. blade may tear someone’s yard up. Blocking primer is the same way: bigger is better, but make sure it is a fit for the job. The last thing you want to do is hit an adjacent panel or molding on the vehicle.

Cross Sand

Cross sanding is sanding in one direction, then cross sand going the other direction. This will produce a level surface. You will also want to use long sanding strokes. Little short strokes may make your finished product to look choppy. Back to the tractor leveling the ground. Would you blade little short passes back up and additional short passes or would you blade with long and even passes across the entire area being leveled? I have never done this kind of work, but I imagine that I would want to use long even passes to level the grade. Therefore, cross sand using long, even passes.

Video Demonstration For Block Sanding Techniques

Work Smarter, Not Harder

Use tools and methods to help make the job easier for you. One of the methods is to use aguide coat. This is a spray or dry coating that you can apply to the surface that has a contrasting color. This will help you identify the lows, scratches, etc. The goal is to sand all the guide coat off without sanding through to the filler or metal. However, DO NOT use the edge of the block or try to sand the guide coat by hand to remove it. If it is not coming off when blocking, then it is doing its job. It is identifying a problem. Now you can fix the problem.

Remember this is the step that counts. This is where you need to have a flawless repair. Whatever is not taken care of during the blocking process will show up in the finished project. So make sure what you see is that the repair is ready for paint.

Final Sanding

We took a long time to get here, but professional bodywork takes time. This is the one time we can say, if there is no body work needed and the paint on the vehicle is in good condition (we’ll talk about what good condition is later) then skip all the other steps and advance to this one. Well, I’m sure that you know that we can’t skip every step…remember proper cleaning. It’s going to stay with you, I promise. Seriously, many times people just want to know how to sand a paint and car…well here it is.

One Dime Equals Two Nickels

I have mentioned earlier that there are many ways to get from “A” to “B.” Many correct ways, but there are always ways you want to avoid, too. The secret is knowing what you can get away with and what you can’t. The end result is what matters, but never sacrifice quality work for speed. I am going to give you several answers for this topic. I do not want to confuse you though. Just pick which one fits you and go with it. However, a word from experience: If you go to work for a shop, they may have an exact system of how they want things done. Never go in there as a know-it-all. That will be the fastest way to make enemies. Once they see that you will work hard and do things the way they want them done, they may listen to an idea that you have. However, prove your work ethics first, as no one likes someone new trying to prove how much you know…they don’t care. All right, off a little. Work ethics is something I focus on with my students. Very important. Back to final sanding.

Wet Sanding

Wet sanding was the preferred method by many and may still be the favored method for some professionals. Wet sanding was the way I was taught and is actually my preferred method. However, with the vacuum systems many shops have, dry sanding systems have became popular, considering environmental concerns of where the waste water drains. It may be required in your state that the water be captured and hauled off by truck to a waste plant. This may be something that you want to check into before determining a method.

Watch Wet Sanding Demonstration

Sizing and Folding

This is how I sanded many cars. If you purchase 3M 400-500 grit wet/dry (black) sandpaper, it normally comes in a 9×11 sheet. If you take the sheet and fold it long ways and tear it, it will give you two pieces of sandpaper. Now take the piece and fold it into thirds. This will make you a nice size to sand with. Be certain to fold the creases tight or the paper will move around on you when sanding. Now you’re ready to start sanding.

Sand One Section At A Time

This is a big tip, which I learned on my own. I used to sand cars with the entire car in my mind the whole time. The job would grow and grow, and grow. The project would become so big in my head; it would actually take me forever to get it sanded. Then I started imagining sections. The hood may be four sections, the fenders would consist of upper and lower and so forth. I would imagine these sections and tell myself that I am not sanding the whole car, I’m just sanding that one small section. Then when I was done with that section, I would move to the next section. Now that was the only section that I was working on. This may sound silly, but it really works. It helps you with a couple of things. First, it breaks the job down into small manageable tasks, rather than one huge overwhelming task. Second, it allows you to thoroughly sand the car without having to go back over it two or three times due to glossy spots. For instance, do not move to the next section until the section you’re working on is completely finished. If you don’t use this method, you may find yourself sanding a little here and a little there, which leads to the missed areas. Lastly, you know exactly where you are at. If you go to lunch or take a break, you can come back and pick back up exactly where you left off without even thinking about it. So one section at one time.

This is a big tip, which I learned on my own. I used to sand cars with the entire car in my mind the whole time. The job would grow and grow, and grow. The project would become so big in my head; it would actually take me forever to get it sanded. Then I started imagining sections. The hood may be four sections, the fenders would consist of upper and lower and so forth. I would imagine these sections and tell myself that I am not sanding the whole car, I’m just sanding that one small section. Then when I was done with that section, I would move to the next section. Now that was the only section that I was working on. This may sound silly, but it really works. It helps you with a couple of things. First, it breaks the job down into small manageable tasks, rather than one huge overwhelming task. Second, it allows you to thoroughly sand the car without having to go back over it two or three times due to glossy spots. For instance, do not move to the next section until the section you’re working on is completely finished. If you don’t use this method, you may find yourself sanding a little here and a little there, which leads to the missed areas. Lastly, you know exactly where you are at. If you go to lunch or take a break, you can come back and pick back up exactly where you left off without even thinking about it. So one section at one time.

The Process

Now, I will share with you a few tips and things to avoid when wet sanding. Remember, if paint is going to peel, it’s going to start from an edge many times. This is why we need to sand the edges extremely well. It is a common mistake to see a student sand the heck out of the easy-to-get areas and do a fast and sloppy job on the hard-to-get-to areas and edges. It should be the exact opposite. Well, we don’t want anything fast and sloppy, but we do need to focus on the edges.

With this in mind, to start, I sand the edges of the section that I’m sanding first. I make sure to get in the crevices, edges, and hard-to-get areas. I also follow up with a scuff pad, but we’ll cover that later. When I get my edges sanded, I switch to a new piece of sandpaper so that it is nice and smooth to sand the remaining portion of the section. Once done, I move to the next section and do the same thing. Use my edge piece for edges and my smooth piece for the flat areas. Easy enough, but are few things that you want to avoid. Always do the edges first. If you do them last you may leave marks in the paint from the sandpaper. Also, use your hand as a block. Do not use your fingers to sand. Use the flat part of your palm creating a block. Sanding with your fingertips may leave marks that show up in the finished paint job. Some professionals use hand pads to eliminate this problem. They work well for the flat areas. One last thing before we move on. When sanding, sand in all directions. You can still use your cross sanding method. However, be sure to make long smooth sanding passes. Short scrubbing style may result in a choppy finish.

Complete Paint Job Made Easy

In a nutshell, wet sand the entire car (if complete paint job) with 400-500 grit sandpaper. Break the job into smaller tasks by imagining sections on each panel. Do not move to the next area until completely done with the area you are working on. Sand the edges first followed by sanding the remaining part of the section. This exact process is how I sanded many cars. Now you’re ready to scuff wash, mask and paint.

Dry Sanding

I am going to pause in the process for just a minute as the remaining steps are going to be the same. As I mentioned, many shops prefer to dry sand, rather than wet sanding. Similar steps can be used, but a different sandpaper is used. One tip when dry sanding is to have a piece of scuff pad and use it to frequently rub it against your sandpaper to clean the sanding dust off. This will also keep the sandpaper from clogging and scratching the paint surface. You can also use a dual action sander with a 6 inch sanding pad. When using a dual action sander when final sanding, always use the interface pad. Below there is a video demonstrating how to final sand a new OEM part. The same process could be used for a complete paint job if needed. This method is much faster than sanding by hand, but requires more skill to control the dual action sander without scratching or marring the surface. Regarding the sanding method, now we can continue the prepping process.

Watch Dry Sanding Using A DA Sander Video Below

Scuff Wash

I don’t know if scuff washing is a textbook term or not, but it’s a system that I developed to assure the vehicle was clean and sanded, and all silicone and other contaminants were removed.

The car has been sanded with 400 to 500 grit sandpaper. Now we’re ready to wash it and get it ready to mask. So scuff washing is using a red scuff pad (when painting the entire car) and Comet or Ajax, and water. Sprinkle a little Ajax on the wet scuff pad (Scotch-Brite) and scrub the vehicle. This is your chance to scuff all the hard-to-get areas and edges extra well. Be sure to get your edges well, but be very careful not to hit molding, glass, chrome or adjacent panels that are not going to be refinished. Nothing looks worse than an awesome looking paint job with sanded and scuffed moldings. Now, this is just an extra step that I take, but you can just dry scuff the entire car if you would rather. I just think that the cleanser helps kill any silicone and contaminants. If you do use the water and cleanser, extra time washing and rinsing the car is needed to make certain that all the residue is completely removed.

WASH

Now the car is scuff washed or dry scuffed, back to the soap and water. Thoroughly wash the car. You also need to keep in mind all the dirt in all the crevices that may end up in the finished paint job if not cleaned properly. So start out by washing the jambs in the engine compartment, door jambs and trunk jambs. Don’t forget to wash wheel well areas. Use a different wash mitt and wash bucket when washing jambs. You do not want the dirty and greasy mix that comes from jambs to get smeared into the wash job of the outside of the car. Once all jambs are washed, I normally shut all the doors, hood and trunk lid, then rinse the entire car off really well. If you have a pressure washer, that works even better.

Now wash the outside of the car from top to bottom and rinse or pressure wash well. Now that we washed the car really well, all the residue from the cleanser and/or sanding dust is off the surface and the car is clean. I usually allow the car to air dry at this point. Blowing with compressed air will speed the drying process, if you need to speed up the process.

THE LAST STEP

I normally do one more step before masking. That is to blow the car off with compressed air. I concentrate on panel gaps, wheel opening, molding, or anywhere else that dirt may be hiding. Now we are ready to mask the car and finally get some paint on it.

MASKING FOR PAINT

I have already discussed masking for primer. Masking for paint follows the same concept, but there are a few things that differ. Remember when I said to mask to the edge when priming? That is because you do not want primer where it does not need to be. Well, with painting, you want to mask about 1/4” inset into the jambs. For instance, you want a little of the paint overspray to lap over the jambs. If you mask to the edges, you will see a hard edge that is very noticeable.

JAMBS FIRST

While I am discussing masking jambs, you also want to do your jambs first. You have to think about it. If you mask the outside of a door first, it may be difficult to open the door without ruining the masking job.

JAMB MASKING TECHNIQUES

There are several different methods to achieve this. One method is to mask 1/4 inch back from the jamb edge. You can use 3/4 inch tape and 3 inch masking paper. However, straight masking with this method will leave a hard edge from the paint.

There are several different methods to achieve this. One method is to mask 1/4 inch back from the jamb edge. You can use 3/4 inch tape and 3 inch masking paper. However, straight masking with this method will leave a hard edge from the paint.

BACK MASKING

This is a reverse mask technique that makes a softer edge. Basically, you simply fold the paper over and allow the tape to be slightly pulled, creating a soft edge. Check out the video and back masking will make sense.

APERTURE TAPE

This is a foam that makes a seal between the two jamb areas. This method works extremely well and is a fairly simple and quick method.

This is a foam that makes a seal between the two jamb areas. This method works extremely well and is a fairly simple and quick method.

TRANSITION TAPE

If you want an absolutely invisible repair, then consider using the transitional tape. This tape is amazing. It has adhesive in the middle of the tape, which creates smooth edge. May or may not be recommended by paint manufacturer, but you can literally apply this tape on a body line and not be able to see the clear coat line. Be sure to watch included videos to grasp the full understanding of these masking techniques.

DO NOT DRAW OUTSIDE OF THE LINES

Remember in kindergarten how the teacher had us outline everything in black? They would tell us to keep it in the lines. Well, masking is a similar process. Now that the jambs are masked and the doors are shut, you can start on the outside of the car. First you need to outline everything with 3/4 inch masking tape. So for example, mask around the doors glass, windshield, back glass, or anything else that you are masking off. One piece of advice when outlining your project: It’s better to have a little paint on the molding than to have the masking tape on the part being painted. You want a clean job, but it’s better to see a trace of paint on a molding than an unpainted chunk on the part. Also, if the paint and clear coat coatings bridge, that is the coatings completely cover the tape and part without a line left behind, you will probably pull a chunk of paint and clear off when unmasking. Besides, you can always clean a little paint off a molding, but a chunk of paint missing is going to require a repaint.

Tips For Masking Windshields and Glass

There are several ways to mask a windshield, which we will discuss. This is a critical area and has caused a lot of problems due to the molding setting close too the paint surface. One of the problem this causes is when the clearcoat is applied. Clear coat requires heavy mills and can bridge over from the painted surface to the tape edge. This means that the clear makes a complete seal filling in the gap. After the clear is dry and the masking tape is removed, this will make a sharp jagged edge. Even worse, if the tape does not pull off straight, it may take a chunk of clear coat off the painted surface, which will result in respraying the panel. The good news, is there are several ways to avoid this problem.

Let’s start off discussing techniques to mask the glass. First, we want to avoid creases in the paper. Creases in the paper creates a place for dust and dry overspray to land. When the pressure from the spray gun hits it from the next coat, it may blow the dust out of the crease and into the paint job. This will require extra buffing, which is extra time spent on the job that could be eliminated.

To create a creaseless masking job, do not bend the masking paper when masking. Easier said than done, but let me go through the steps with you. First, use ¾ masking tape to outline the glass molding. Then using 18 inch masking paper with ¾ inch tape to cover the remaining portion of the glass. It is best to tear of sheets off the masking paper to cover the entire length of the glass with one sheet to eliminate seams that will need to be masked. Now start by placing the masking tape on the masking paper to the center section of the masking tape that is already attached to the car. From the center, pull each side of the masking paper straight back making a straight line. This will probably not follow the molding, but that is alright. If you follow the molding, the paper will create creases, which is what we want to eliminate. Now that the paper is straight across the glass area, use a razor blade to cut the paper around the molding. Care must be taken not to cut the glass or molding. This can be done by holding the paper up while making the cut. Once the masking paper has been cut to fit, use ¾ inch tape to mask around the remaining edges. Now the paper should be masked completely around the glass to the tape that we used to outline the glass molding with.

If you use this method you will have minimal creases in your masking paper. If you do have a crease, tape the crease solid using masking tape. If one layer does not completely cover the width of the glass use another piece of paper on the other end and repeat the process. Once all edges are completely taped, mask the seam of the two layers of masking paper. When completed, all edges, creases, and seams should be taped. This will complete a seal, which will eliminate overspray from entering the paper and getting on the glass or molding. This will also eliminate pockets and creases in the masking paper that can attract dry overspray and dust. This will provide a cleaner job and less dirt in the finished paint job. This will result in less sanding and buffing after the paint job is completed to remove dirt nibs.

How To Avoid The Clear Coat From Bridging on Molding That Fit Close To or Touch The Painted Surface Being Sprayed

Many times a molding fits tight against or even touches the painted surface. The problem with this is that the clear coat may fill in the gap or crack between the molding and paint surface. In other words, the clear coat bridges over from the painted surface to the masking tape. When the paint is dried and the masking tape is removed, the clear coat will have a rough edge from the clear coat. Even worse, it may even pull a chunk of clear coat from the painted surface. If this happens, the surface may have to be sanded, re-painted, and cleared.

There are several ways to avoid this. If the glass molding is soft and flexible enough a small diameter rope can be used to shove under the molding. This will lift the edge of the molding up, which will allow the paint coating to flow underneath the molding. Once the paint is dry, remove the rope, which will allow the molding edge to sit back on top of the newly painted surface.

There is also a special masking product, which has a hard plastic edge on one end and adhesive tape on the other end. First place the hard plastic edge underneath the edge of molding. Then fold the adhesive side over and stick to the glass. This will lift the edge of the molding up, which will allow paint coatings to flow underneath the moding. When the trim mask is removed, the edge of the molding will set back on top of the newly painted surface.

Sometimes the molding is too rigid and the molding is difficult to lift. In these cases, there is another method that can be used. When outline the molding with ¾ inch masking tape, leave about ⅛ inch of the molding exposed. Then mask the glass as you normally would using masking paper. Once completely masked, use ¼ inch fine line tape to go around the edge of the molding. This tape will cover the the molding edge and the masking tape that was used to outline the molding. It is important to apply the i/4 inch tape last so it will be easy to pull off. Immediately after applying the last coat of clear coat, pull the ¼ inch tape from the molding. Care needs to be taken not to let the tape hit the fresh clear coat finish. This will produce a smooth transition instead of creating a hard edge if removed after the clear has dries. This will also eliminate the risk of pulling a chunk of clear from the painted surface.

A Tip For Masking Hose Lines and Wiring

Another problem you may run into when masking is masking off hoses and wiring. I have seen them wrapped in masking tape, but the problem is unmasking. This can be a tedious time consuming job. However, there is a quick fix for these parts. Use aluminum foil to wrap around these parts. The foil will form around the part to protect the part from paint. The cool thing is that the foil is as easy to remove as it is to put on. This works great for parts such as: fuel lines, door wiring harness, inside door parts when paint the inside of a door, inside door handle, etc.

Tips For Covering Holes

To mask holes such as tail light access holes, windshield wiper holes, door handle access holes, place masking tape to the back side of the hole to seal the hole shut. Let’s say you have the car masked off and you realize a small windshield washer hole is not masked off. Before you start opening your door and hood ruining the masking job, try this little trick. If it is a small hole, use a foam ear plug. You can squeeze the ear plug making it small to fit inside the hole, then as it expands, it will seal the hole shut. Of course, this will not work for large holes, but the larger holes are as often overlooked when masking. It’s the small holes that is often forgotten about until the car is already masked off. Well, that should not be a problem now!

Resources

•www.CollisionBlast.com/HowToPrepBeforePrime – In this video, I demonstrate how to prep the entire panel before priming. This will eliminate the primer from getting on un-sanded paint.

•www.CollisionBlast.com/FeatherEdge – This video demonstrates the idea of featheredging.

•www.CollisionBlast.com/FianlSandOEMPartDrySand – This video demonstrates a method to sand and prepare a new body part when replacement is required.

•www.CollisionBlast.com/WetSand – This is a quick video where I demonstrate how to sand using a wet sanding method.

•www.CollisionBlast.com/MaskBeforePrime – In this video I demonstrate how to mask before using primer. Remember to mask to edges to prevent primer from wrapping around jamb or getting in the jamb area.

•www.CollisionBlast.com/FoamTape – This video demonstrates how to use foam tape for jambs. This is for a smooth transition in jambs.

•www.CollisionBlast.com/TransitionalTape – This is a 3M video that demonstrates how to use their transitional tape. This works great for jambs to leave an invisible paint line.

•www.CollisionBlast.com/HowToMixEpoxyPrimer – This video demonstrates how to mix epoxy. Remember that some epoxies require an induction time.

•www.CollisionBlast.com/SprayingEpoxyPrimer – This video demonstrates how to spray epoxy primer.

•www.CollisionBlast.com/HowToMixAndSprayPrimerSurfacer – This video demonstrates how to mix and spray primer surfacer.

•www.CollisionBlast.com/HowToBlockSandPrimerSurfacer – This video demonstrates how to block sand primer surfacer.

•www.CollisionBlast.com/BlockSandingTechniques – In this video I am demonstrating how to block sand using Motor Guard sanding blocks.

•www.CollisionBlast.com/DifferenceBetweenPrimers – This is a quick video answering some questions I received about the difference between primers.

•www.CollisionBlast.com/3MPrepForBlending – Video tutorial by 3M that explains how to prep for blending.

Learn more about the tools and materials used for dent repair. Below you will find some of the most common tools and supplies

Featheredging

•www.CollisionBlast.com/3MDA220 – This is 3M’s 6 inch sandpaper to be used on a DA sander for feather edging.

•www.CollisionBlast.com/DASander – This is a 6 inch sander used for featheredging and final sanding. This sander is made by CP Tools and works well at a reasonable price.

Spray Guns

•www.CollisionBlast.com/Accuspray – This is a great spray gun for spraying primer surfacer. The gun comes with a 1.8 fluid tips, which works best for primer surfacer.

•www.CollisionBlast.com/Devilbiss – This is a spray gun that comes with a 1.2, 1.3, and 1.4 fluid tip. The 1.3 works well for base coat and clear coat. I have found this spray gun to work as well as the higher end guns.

•www.CollisionBlast.com/SharpeFinex – If you are just looking for a good spray gun for base coat and clear coat on a budget, than I recommend this gun. We have used it with great results.

•www.CollisionBlast.com/BuyIwata – This is my spray gun of choice. It is a great spray gun for base coat and clear coat, but the price is more than the other spray guns.

Masking

•www.CollisionBlast.com/MaskingPaper – Paper for masking of a car.

•www.CollisionBlast.com/3/4MaskingTape – This is the most common tape used in a body shop and fits of of the masking machines.

•www.CollisionBlast.com/1-1/2MaskingTape – 1 1/2 inch masking tape works great for jamb, back masking, taping plastic to paper and many other uses.

•www.CollisionBlast.com/MaskingMachine – Masking machines.

Primers

•www.CollisionBlast.com/KustomShopEpoxyPrimer – This is another brand of epoxy primer used by many custom painters.

•www.CollisionBlast.com/ShopLinePrimerSurfacer – This is primer surfacer used as a filler primer.

Block Sanding

•www.CollisionBlast.com/GuideCoat – Guide coat helps identify highs and lows. Do not skip this step, as it will save you time in the end.

•www.CollisionBlast.com/220ForBlocking – 220 Dry grit sandpaper can be used for block sanding primer surfacer.

•www.CollisionBlast.com/320ForBlocking – 320 Dry grit sandpaper can be used to remove the 220 grit scratches.

•www.CollisionBlast.com/220WetBlockSand – If using a wet sanding method, this is 220 grit sandpaper to be used for block sanding.

•www.CollisionBlast.com/320WetBlockSand – 320 wet sandpaper can be used to remove the 220 grit sand scratches.

•www.CollisionBlast.com/400FinalSandDry – Used for final sanding to prepare the paint surface for paint.

•www.CollisionBlast.com/400FinalSandWet – Used for final sanding to prepare for paint when using a wet sanding system.

•www.CollisionBlast.com/AP-3 – These are new sanding blocks made by Motor Guard. They have some new blocks, which work awesome. This combination of blocks will work for all of your block sanding. These blocks can be used for dry or wet sanding.

•www.CollisionBlast.com/3MSandingSystems – 500 grit sandpaper can be used on a 6 inch sander.

•www.CollisionBlast.com/InterfacePad – This pad should be used on a DA sander when final sanding.

Product Technical Data Sheet

It is always important to read the TDS for any products are supplies you use. This is the information that tells you exactly how to use the specific product you are using. Note that one TDS may not be equal from different brands. If other brands are used, ask your supplier to provide this for you. There may also also be directions on the can or package, but the TDS is more detailed.

- www.CollisionBlast.com/TDSKustomShopEpoxy

- www.CollisionBlast.com/TDSShoplineEpoxy

- www.CollisionBlast.com/TDSKustomShopSurfacer

- www.CollisionBlast.com/TDSShoplineSurfacer

- www.CollisionBlast.com/TDSGuideCoat

Every product that contains chemicals has a MSDS. This provides all of the hazards of the products, who you needs to contacted in case of an emergency, flammability, etc.

- www.CollisionBlast.com/MSDSKustomShopEpoxy

- www.CollisionBlast.com/MSDSKustomShopEpoxyCatalyst

- www.CollisionBlast.com/MSDSShoplineEpoxy

- www.CollisionBlast.com/MSDSKustomShopSurfacer

- www.CollisionBlast.com/MSDSKustomShopSurfacerCatalyst

- www.CollisionBlast.com/MSDSShoplineSurfacer

- www.CollisionBlast.com/MSDSGuideCoat

Stop by a body shop or dealership and ask them if they have an old damage part you could have or buy. Use this part and perform the steps provided in this book. Do not rush through the cleaning or prepping steps.

What problems did you have during the preparation process? Write each problem down and try to determine what caused the problem and how to eliminate the problem from happening again.

NOTE: If you are a student attending a collision repair program or an employee at a repair facility, review the steps below and discuss them with your instructor or supervisor. After the discussion, determine if this outline fits with your schools curriculum or shop procedures. If this needs to be tweaked, write or type the steps to take at your specific school or repair facility. Once completed, add the steps to your notebook for future reference.

NOTE: If you are a student attending a collision repair program or an employee at a repair facility, review the steps below and discuss them with your instructor or supervisor. After the discussion, determine if this outline fits with your schools curriculum or shop procedures. If this needs to be tweaked, write or type the steps to take at your specific school or repair facility. Once completed, add the steps to your notebook for future reference.

Paint Complete Panel That Had Damage Repaired

1.The body work is completed and finished out in 150 grit sandpaper.

2.Featheredge around the repair area layering each layer of coating at least 1/4” with 220 using a DA – No interface pad needed for this step.

3.Final sand the entire panel (we’re painting the entire panel) using a DA sander, interface pad and 500 grit sandpaper.

4.Scuff the entire fender area with a red scuff pad. Focus on edges and hard-to-get areas.

5.Blow with compressed air and wipe with wax and grease remover.

6.Mask adjacent panels to prevent overspray.

7.May need to cover car with plastic to prevent overspray.

8.Wipe once again to remove any fingerprints and other contaminants.

9.Mix epoxy primer – check to see if there is an induction time.

10.Apply the recommended number of coats to the damaged area. (Corrosion protection)

11.Mix and apply primer surfacer to damaged area. (Filling)

12.Note: Remember it is only necessary to prime the damaged area, not entire fender.

13.Apply guide coat.

14.Dry block sand with 220 grit sandpaper until guide coat is removed

15.If low areas or other imperfections still exist, repeat the primer and blocking step.

16.If the repair area is blocked out well, switch to 320 grit and block out 220 scratches.

17.Using the DA sander with 500 grit and the interface pad, sand the repair area overlapping to the previous sanded area.

18.Scuff wash the panel with red scuff pad. (Comet optional)

19.Wash with dish soap and water.

20.Blow dry.

21.Mask jambs.

22.Outline adjacent panels.

23.Mask using 18” around outline.

24.Cover car with plastic and tape plastic edge to paper. Note: Do not have plastic too close to the area that you are painting. The dry paint may blow off when the air pressure of the gun hits it. This may result in a big paint flake in your paint job.

25.Now you’re ready to wipe, tack and start the spraying process, which we’ll cover in the next lesson.

Tip: You may also want to tape adjacent panels during the sanding process to prevent accidentally hitting the surface, causing scuff marks and scratches. Same goes for molding and chrome.

Steps For Complete Paint Job…No Body Work.

1. Wash entire car thoroughly with dish soap and water.

2. Wipe with wax and grease remover.

3. Remove all possible parts. Get a baggy for each part and use a sharpie to write the part name on it. Right tail light, right door handle, etc. and put all of the hardware in the labeled baggies. Then put parts in a large container for storage.

4. Remove any stripes or decals

5. Mask chrome or molding to prevent scuff marks.

6. Sand the entire car one section at a time with 500 grit on a DA with interface pad, or with 400 grit wet sanding method using a soft hand pad. Only sand enough to dull surface. A flat surface with no gloss is the goal.

7. Scuff wash the entire vehicle with red scuff pad, focusing on edges and hard to get areas. (Comet optional)

8. Wash entire vehicle with dish soap and water. Rinse very well. If comet was used you may want to wash twice to assure all residue is off.

9. Blow dry with compressed air.

10.Mask jambs.

11.Outline glass, moldings, etc. with 3/4” masking tape.

12.Mask the outlined areas with 18” masking paper.

13.Now we’re ready to wipe, tack and start spraying.

Steps For Blending Within a Panel

1. The body work is completed and finished out in 150 grit sandpaper.

2.Featheredge around the repair area layering each layer of coating at least 1/4” with 220 using a DA – no interface pad needed for this step.

3.Final sand the entire panel (we’re clear coating the entire panel) using a DA sander, interface pad and 800 grit sandpaper.

4.Scuff the entire fender area with a gray scuff pad. Focus on edges and hard-to-get areas.

5.Blow with compressed air and wipe with wax and grease remover.

6.Mask adjacent panels to prevent overspray.

7.May need to cover car with plastic to prevent overspray.

8.Wipe once again to remove any fingerprints and other contaminants.

9.Mix epoxy primer – check to see if there is an induction time.

10. Apply the recommended number of coats to the damaged area. (Corrosion protection)

11. Mix and apply primer surfacer to damaged area. (Filling) Note: Remember it is only necessary to prime damaged area, not entire fender.

12. Apply guide coat.

13. Dry block sand with 220 grit sandpaper until guide coat is removed.

14. If low areas or other imperfections still exist, repeat the primer and blocking step.

15. If the repair area is blocked out well, switch to 320 grit and block out 220 scratches.

16. Using the DA sander with 500 grit and the interface pad, sand the repair area overlapping to the previous sanded area.

17. Scuff wash the panel with gray scuff pad. (Comet optional)

18.Wash with dish soap and water.

19. Blow dry.

20. Mask jambs.

21. Outline adjacent panels.

22. Mask using 18” around outline.

23. Cover car with plastic and tape plastic edge to paper. Note: Do not have plastic too close to the area that you are painting. The dry paint may blow off when the air pressure of the gun hits it. This may result in a big paint flake in your paint job.

24. Now you’re ready to wipe, tack and start the spraying process, which we’ll cover in the next lesson.

A Blend Panel With No Damage – Blending for color matching only

1.Wash entire panel thoroughly with dish soap and water.

2.Wipe with wax and grease remover.

3.Remove parts, door handle, etc.

4.Remove any stripes or decals.

5.Mask chrome or molding to prevent scuff marks.

6.Sand the panel using 800 grit on a DA with interface pad, or with 800 grit wet sanding method using a soft hand pad. Only sand enough to dull surface. A flat surface with no gloss is the goal.

7.Scuff wash the part with gray scuff pad focusing on edges and hard-to-get areas. (Comet optional)

8.Wash part with dish soap and water. Rinse very well. If Comet was used you may want to wash twice to assure all residue is off.

9. Blow dry with compressed air.

10. Mask jamb.

11. Outline glass, moldings, etc. with 3/4” masking tape.

12. Mask the outlined areas with 18” masking paper.

13.Now we’re ready to wipe, tack and start spraying.

I would like to stress the importance of preparation in order to produce a quality paint job. Preparation is perhaps the most important step for producing stellar results. Do not cut any corners or take any shortcuts during the prepping steps.

Metal Repair Key Terms

•ABRASIVE: Substance used to wear away a surface by friction.

•ABRASIVE COATING: In closed coat paper, the adhesive is completely coated with abrasive, and in open coat paper, the adhesive is partially exposed, for the abrasive is not put on the paper close together.

•ADHESION: The quality or condition of sticking together or holding fast.

•ADHESION LOSS OR FAILURE: Reduction of bonding, resulting in the paint peeling.

•CHEMICAL ADHESION: Adhesion produced by chemicals.

•MECHANICAL ADHESION: Adhesion promoted by a rough surface.

•ACTIVATOR: Additive used to speed up the curing of paint resins.

•ANTICORROSIVE: Materials applied to metal to give corrosion resistance.

•ANTICORROSIVE AND INHIBITOR: Protective coatings applied on metal surfaces to retard or prevent corrosion and said to be anticorrosive or corrosion inhibitive.

•APERTURE TAPE: Used to provide a smooth transaction of paint coatings. Also known as rope tape used in jamb areas to eliminate hard edges.

•BACK MASKING: The process of masking an area and folding it backwards to provide a smoother paint line.

•BLENDING: Mixing together of two or more materials or the gradual shading of paint from one panel to the next.

•BLENDING PREPARATION: The process of sanding a panel that paint will be blended. Part of the panel will only be clear coated; therefore, a finer grit sandpaper must be used.

•CATALYST: Substance that causes or speeds up a chemical reaction when it is mixed with another substance and that does not change by itself.

•CONTAMINANTS: Any polish, wax, tree sap, tar, oil, and the like that would damage the paint film or spoil the adhesion of a new paint film.

•DRY SANDING – A method used to sand the substrate without the use of water.

•DUST FREE: Condition when a film has dried so that it will no longer allow dust to penetrate and stick to the finish.

•E-COAT: Is electrocoating, also known as electrophoretic painting or electropainting. It’s an organic finish which is often applied as a prime coat on steel. This is the black primer used on new parts.

•EPOXY PRIMER: Epoxy primer/sealer is a non-porous finish that is typically recommended as the first basecoat over bare steel. Provides excellent corrosion protection and adhesion.

•FEATHEREDGING: Sanding down a surface to a very fine edge; that is when one coat of material is made gradually thinner around the edge until it finally disappears.

•FLASH TIME – The amount of time that is recommended to wait between refinish coatings.

•GRIT: Small, loose particles of stone or sand. In regards to sandpaper, 400 grit is a finer sandpaper than 36 grit sandpaper. It takes 400 small grits of sand to make a square inch of sandpaper. It takes 36 larger grits of sand to fill the same square inch for 36 grit sandpaper.

•GUIDE COAT: Coat of a different color from the other coat is used to serve as a guide coat in rubbing or sanding to determine when a smooth surface has been reached.

•HARDENER: Special additive designed to promote a faster cure of the enamel paint film.

•HARD TAPE LINE: A hard paint edge caused by a coating being sprayed against a tape line. Can be useful for two-tones and stripes, but does not look good in jamb areas where there should not be a paint break.

•FINAL SAND: The last sanding step before painting.

•MASKING: Application of paper or other material and masking tape to cover an object that must be protected from overspray.

•MASKING PAPER: Paper designed to prevent paint bleeding through and resist water soaking to a certain degree.

•MASKING TAPE: Special paper that is coated with adhesive used to protect body parts or to attach masking paper to the car.

•MIL: Measure of film thickness equal to 0.001 inches.

•O. E. M.: Original equipment manufacturer. Usually refers to replacement parts for a vehicle that were made by the same manufacturer as the car, rather than replacement parts made by a different manufacturer.

•ORBITAL SANDER: Type of sander that uses an orbit motion to accomplish the sanding of different materials.

•ORIGINAL FINISH: Paint the car manufacturer applies at the factory.

•OVERALL REPAINTING: Refinish repair job in which the whole vehicle is completely repainted.

•OVERLAP: Amount of the spray pattern that covers the previous spray swath.

•OVERSPRAY: Excess coatings when sprayed.

•POT LIFE: The time a coating has before it starts to harden and become a solid.

•PRIMER: Undercoat applied to improve the adhesion of the color coat.

•PRIMER COAT: Used in a paint system to improve adhesion; requires sanding.

•PRIMER-SEALER: Undercoat that improves the adhesion of the topcoat and seals the old painted surfaces.

•PRIMER-SURFACER: High-solid type of primer used to fill small imperfections in a substrate.

•REDUCER: Referred to as the volatile substance used to thin the viscosity of enamel prior to application.

•REFINISH: Term used to designate that a part or a vehicle is to be repainted.

•RESPIRATOR: Filtering device worn over the mouth and nose to filter out particles and fumes and prevent them from reaching the lungs.

•SAND: The process of using sandpaper to provide mechanical adhesion to a substrate.

•SAND SCRATCH SWELLING: exaggerated reproduction and distortion of the sanding marks in the underlying surface.

•SAND SCRATCHES: Reproduction in the topcoat of the sanding marks in the underlying surface.

•SANDBLASTER: Piece of equipment used to clean metal using sand and pressurized air.

•SANDER: Power driven tool used with abrasives to sand car bodies.

•SANDER POLISHER: Power tool used to speed up the rate of polishing or sanding surfaces.

•SANDING BLOCK: Hard rubber or plastic flexible block used to provide consistent backing for hand sanding.

•SCUFF SAND: To lightly sand a surface with an abrasive pad.

•SCUFF WASH: Using an abrasive pad to wash a paint surface to prepare for painting.

•SETTING UP: Period during which solvent evaporation from the film flowing ceases and the film surface becomes tack free.

•SELF ETCHING PRIMER: Self-etching primer is composed of an acid and zinc. The acid, usually phosphoric acid, forces the zinc down into the top couple of molecules of the steel. Works well for corrosion protection

•SPRAY GUN: Device that mixes paint and compressed air to atomize and control the spray pattern as the paint leaves the fluid needle and cap.

•SUBSTRATE: Surface to be painted whether an old finish or bare metal.

•THINNER: Commonly known as a lacquer solvent, which reduces the viscosity of a lacquer to spraying consistency.

•WET SANDING: Procedure of sanding paint film with sandpaper and water.

•WINDOW TIME: The amount of time paint will provide a chemical bond without providing a mechanical adhesion. (The amount of time you have to apply another coating without sanding the substrate.)

Paint Prep Quiz

Now test your knowledge. There is not a time limit set on this quiz so take your time. Find the correct answer if you do not know for sure. The objective of this quiz is to help you learn the information if you do not know the answer, not guessing. Good Luck!

Paint Prep Quiz – Password (simple)

Copyright 2011 CollisionBlast.com

If Something Is Worth Doing, then Do Your Best and Have a BLAST Doing It

CollisionBlast.com