When welding thin sheet metal such as body panels on cars, a solid wire works best when using a MIG welder. To use a solid wire you must use a shielding gas. However, most MIG welders do not come with a bottle. If the welder claims it is ready to weld without the need to use a shielding gas, it’s probably set-up to use flux-core wire.

This is no big deal, as it is easy to convert the welder to use solid wire. Although, without any guidance, you may not be aware of the difference. Flux-core is not recommended for auto body repair. To switch, you will need to change the polarity from straight polarity to reverse polarity. Next, you will need to buy solid wire. A common wire used for collision repair shops is ER70S-6. Then you will need to get a bottle shielding gas to use.

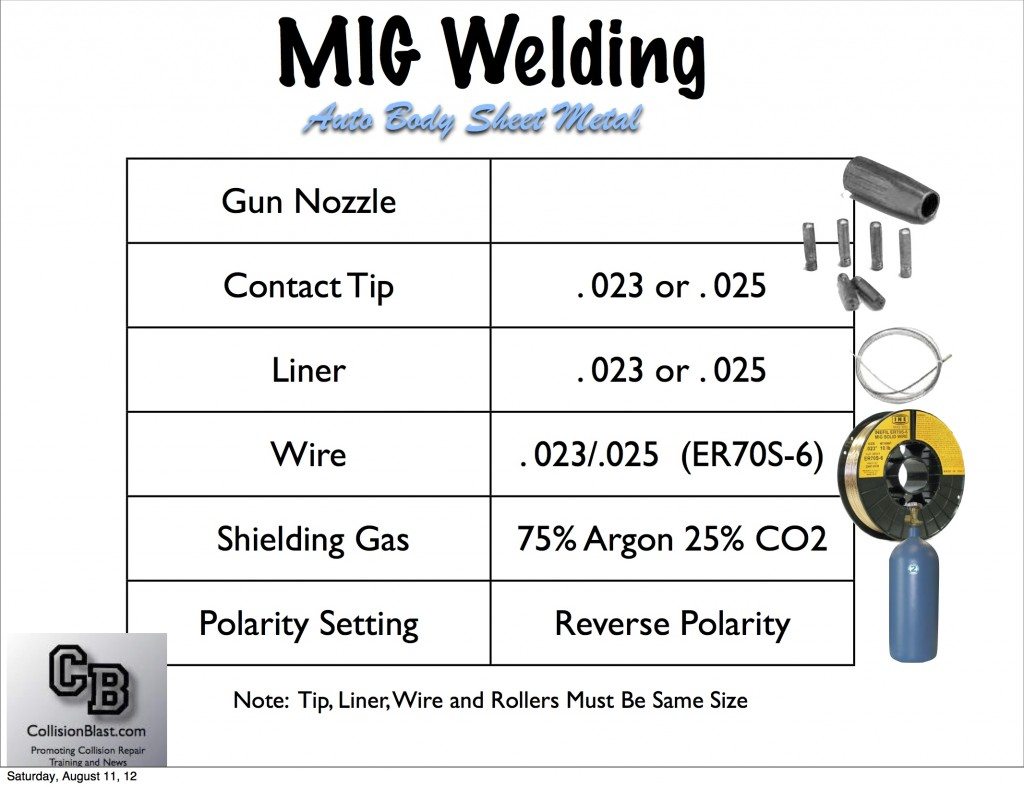

That is it! For additional information, such as wire size, watch the video. Below is chart with the recommendations for auto body welding.

For a PDF copy of the MIG welding chart visit: http://www.collisionblast.com/wp-content/uploads/2012/08/mig-welding-chart-pdf.pdf

For free access to hours of free auto body and paint training visit http://CollisionBlast.com

If you have not already, be sure to also subscribe to this YouTube channel at http://YouTube.com/ButlerCollision

BDR Stainless – Superior Steel Fabrications in Brisbane says

BDR Stainless – Superior Steel Fabrications in Brisbane says

November 8, 2013 at 8:46 amYour video presentation regarding the basics of MIG welding is amazing. I appreciate it.