We’ve have the quarter panel section location welded and now we are going to apply fiberglass filler to the weld location. However, doing a project little by little like this outside, we primed the weld location to prevent it from rusting until we worked on the Mustang again. So in addition to grinding the weld, we also had to remove the primer before applying the fiberglass filler.

[youtube]http://www.youtube.com/watch?v=lQsX6sAcy6U[/youtube]

Before applying fiberglass to the welds, the repair area must be ground to metal. After completing the weld in the last video, I primed the metal to prevent rusting. Now the primer and surounding surface must be ground to metal to assure proper adhesion.

Before applying fiberglass to the welds, the repair area must be ground to metal. After completing the weld in the last video, I primed the metal to prevent rusting. Now the primer and surounding surface must be ground to metal to assure proper adhesion.

Fiberglass filler is a filler that has fiberglass strands mixed in it. This type of filler should be applied over weld locations to seal the weld location to prevent corrosion.

Fiberglass filler is a filler that has fiberglass strands mixed in it. This type of filler should be applied over weld locations to seal the weld location to prevent corrosion.

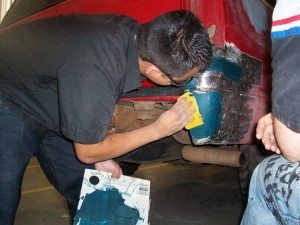

Fiberglass filler mixed similar to body filler. Using a mixing board, add the amount of fiberglass needed for the repair. Then mix the same amount of cream hardener as you would with regular body filler. Mix the two parts together until you have one uniform color. Now you are ready to apply the fiberglass filler over the weld location.

Using a spreader, spread the filler over the weld location. Make sure all of the weld is coated with fiberglass to assure the weld is completely sealed.

Once the fiberglass filler is applied, use a sanding block to level the fiberglass. Do not worry about trying to make the fiberglass perfect at this point, as fiberglass does not finish out as well as body filler. Once level, body filler may be applied over the fiberglass for final shaping.

Leave a Reply

You must be logged in to post a comment.